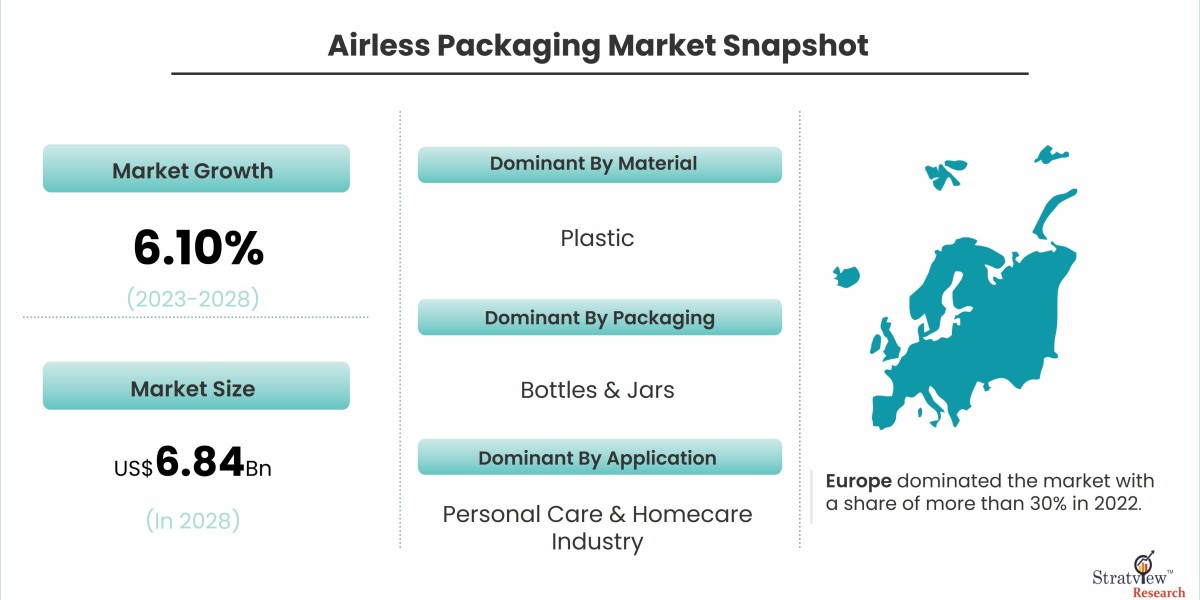

According to Stratview Research, the airless packaging market was estimated at USD 4.8 billion in 2022 and is likely to grow at a CAGR of 6.10% during 2023-2028 to reach USD 6.84 billion in 2028.

In the dynamic realm of packaging, a revolution is underway, and its name is Airless Packaging. Pressurizing the way we perceive product preservation, airless packaging solutions have emerged as a transformative force in the industry. Beyond the conventional, this technology is rewriting the rules of protection, shelf life, and consumer experience. In this exploration, we uncover the revolutionary aspects that make airless packaging a game-changer, redefining how products are pressurized and protected.

The Essence of Pressurization: Airless packaging introduces a groundbreaking concept – the essence of pressurization. Unlike traditional pump dispensers, airless systems leverage a vacuum effect, creating a pressurized environment within the packaging. This pressurization becomes the cornerstone for preserving the integrity of the product within.

Extended Preservation Periods: The core revolution lies in the extended preservation periods afforded by airless packaging solutions. By pressurizing the product, exposure to air is minimized, reducing oxidation and contamination risks. This results in products with a significantly longer shelf life, a critical factor for industries ranging from cosmetics to pharmaceuticals.

Precision in Dispensing: Airless packaging takes precision in dispensing to new heights. The pressurized mechanism allows for controlled and accurate dispensing of the product. Consumers benefit from the ability to extract the desired amount without the guesswork often associated with traditional pump systems.

Sealed Protection Against Contaminants: Pressurization serves as a sealed shield against contaminants. The vacuum effect ensures that the product remains sealed within the packaging, safeguarding it against external elements such as air, light, and bacteria. This protection is particularly vital for sensitive formulations in the beauty and pharmaceutical sectors.

Elevating Sustainability: The revolution of airless packaging extends to sustainability. Pressurization reduces the need for excessive preservatives, as the sealed environment hinders microbial growth. This eco-friendly approach aligns with global sustainability goals, emphasizing reduced waste and a more environmentally conscious packaging solution.

Material Innovation for Enhanced Pressurization: Material innovation plays a crucial role in the pressurization capabilities of airless packaging. Advanced materials, often leveraging high-performance plastics or other durable polymers, enhance the structural integrity of the packaging, contributing to the effectiveness of the pressurized system.

Adapting to Diverse Industries: The revolution in airless packaging is adaptable across diverse industries. From cosmetics and personal care to pharmaceuticals and food products, the pressurized protection offered by airless solutions addresses the specific needs of each sector, showcasing the versatility of this packaging technology.

Customized Pressurized Solutions: Brands are increasingly seeking customized pressurized solutions. Whether it's adapting the level of pressurization for specific product viscosities or tailoring the design to align with brand aesthetics, airless packaging offers a customizable approach that caters to the unique requirements of each brand.

Pressurized Elegance in Luxury Packaging: In the realm of luxury packaging, pressurization brings a new level of elegance. The sleek and streamlined designs of airless packaging not only exude luxury but also communicate the sophistication associated with pressurized protection for high-end formulations.

Consumer-Friendly Dispensing: Consumers benefit from the user-friendly dispensing experience facilitated by pressurized airless systems. The absence of air in the packaging minimizes the risk of clogs and ensures a smooth, consistent flow of the product, enhancing the overall user experience.

Digital Integration for Smart Pressurization: Pressurization meets the digital era through smart packaging solutions. Airless packaging can integrate technologies such as QR codes or NFC tags, allowing brands to engage with consumers, provide product information, and ensure that pressurized protection is coupled with digital interactivity.

Safety Assurance Through Pressurized Seals: Pressurization acts as a seal of safety. The airtight environment created within airless packaging ensures that the product remains untainted from external contaminants, providing consumers with the assurance of safety and hygiene, a critical aspect in today's health-conscious landscape.

Global Acceptance of Pressurized Technology: The revolution of airless packaging, with its pressurized technology, is not confined to specific regions. Its global acceptance is evident as industries worldwide recognize the benefits of pressurized protection, marking a shift towards a standardized and effective packaging solution.

Continuous Research and Development in Pressurized Systems: The dynamism of the airless packaging revolution is sustained by continuous research and development. Manufacturers invest in exploring new pressurized systems, materials, and designs, ensuring that airless packaging remains at the forefront of technological advancements.

Pressurization as a Future Standard: As we explore the revolution of airless packaging solutions, it becomes evident that pressurization is not just a trend but a future standard. The technology is reshaping how we view packaging, emphasizing protection, sustainability, and consumer-friendly features that are poised to become the norm in the evolving landscape of product packaging.

Conclusion: Pressurize and Protect: The Revolution of Airless Packaging Solutions is not merely a tagline; it encapsulates a transformative journey in packaging technology. As pressurized systems redefine preservation, precision, and sustainability, airless packaging emerges as a beacon of innovation. The future of packaging is pressurized, offering brands and consumers alike a revolutionized approach that goes beyond conventional norms, ensuring that products are not just packaged but preserved with precision and protected with unparalleled efficacy.