In the ever-evolving landscape of elastomers, Fluorosilicone Elastomer, commonly known as FVMQ, has emerged as a critical player, offering a unique blend of properties that cater to demanding applications. This blog delves into the dynamic realm of the global Fluorosilicone Elastomer market, exploring its demand dynamics, applications, technological advancements, and future growth prospects.

Understanding Fluorosilicone Elastomers (FVMQ):

Fluorosilicone Elastomers (FVMQ) are synthetic rubber compounds renowned for their exceptional resistance to extreme temperatures, fuels, oils, and solvents. This elastomeric material combines the inherent flexibility of silicone with the chemical resistance of fluorocarbons, making it a preferred choice in industries where traditional elastomers may fall short.

Demand Drivers:

Aerospace Applications: FVMQ finds extensive use in aerospace applications, including seals, gaskets, and O-rings, where the material's resistance to aviation fuels and extreme temperature variations is crucial.

Automotive Advancements: As automotive technologies continue to evolve, FVMQ plays a pivotal role in sealing solutions, fuel system components, and gaskets due to its resistance to automotive fluids and temperature extremes.

Electronics and Electrical Industry: The electronics sector benefits from FVMQ's electrical insulating properties, making it an ideal material for gaskets, seals, and components in electronic devices and systems.

Oil and Gas Exploration: FVMQ's resistance to harsh chemicals positions it as a valuable material in oil and gas applications, particularly in seals and gaskets for downhole tools and equipment.

Market Insights:

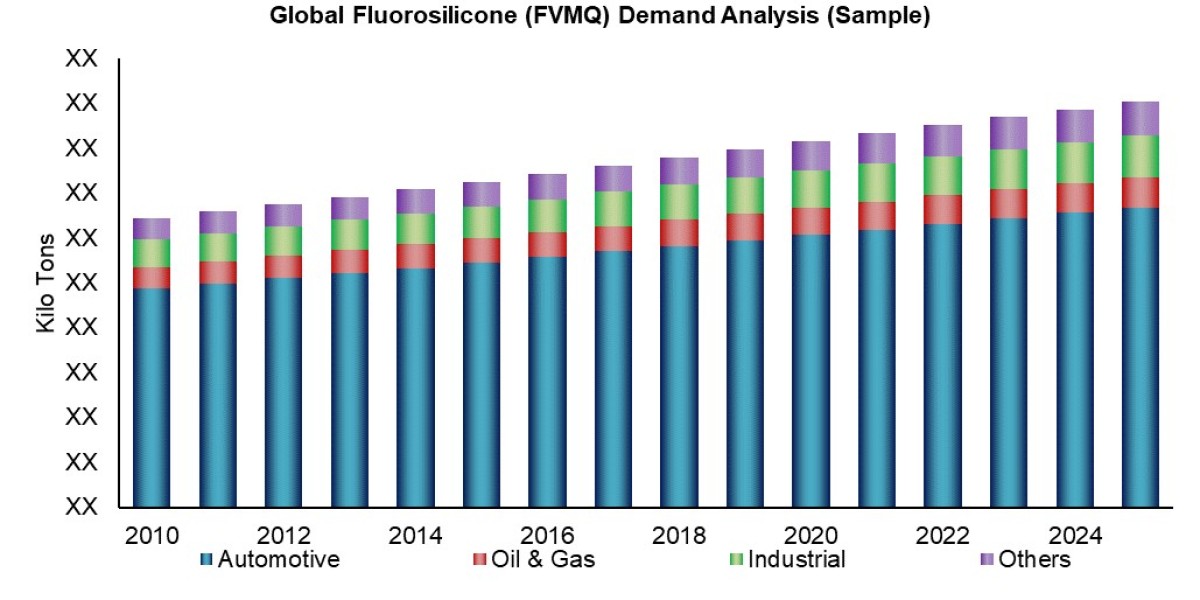

Growing Demand for High-Performance Elastomers: Industries seeking reliable materials for extreme environments are driving the demand for FVMQ, contributing to the market's sustained growth.

Technological Advancements: Ongoing research and development efforts focus on enhancing FVMQ's performance characteristics, expanding its application scope and ensuring it meets the evolving demands of various industries.

Customization for Specific Applications: Manufacturers are increasingly offering customized FVMQ formulations tailored to specific industry needs, further widening its adoption in diverse sectors.

Applications Across Industries:

- Aerospace: Seals, gaskets, O-rings, and other critical components.

- Automotive: Gaskets, seals, fuel system components, and engine components.

- Electronics and Electrical: Gaskets, seals, and components in electronic devices and systems.

- Oil and Gas: Seals and gaskets for downhole tools and equipment.

Future Growth Prospects:

The global Fluorosilicone Elastomer market is poised for substantial growth, driven by the increasing demand for materials capable of withstanding extreme conditions. As industries continue to push technological boundaries and explore harsher environments, FVMQ's unique combination of properties positions it as a key player in the future of high-performance elastomers.

Conclusion:

Fluorosilicone Elastomers have cemented their place as a crucial material in industries requiring resilience in the face of extreme conditions. As the global demand for high-performance elastomers rises, understanding the dynamics of the Fluorosilicone Elastomer market becomes imperative for businesses and stakeholders. With a promising future shaped by technological advancements and expanding applications, FVMQ stands tall as a versatile and indispensable material in the world of elastomers.