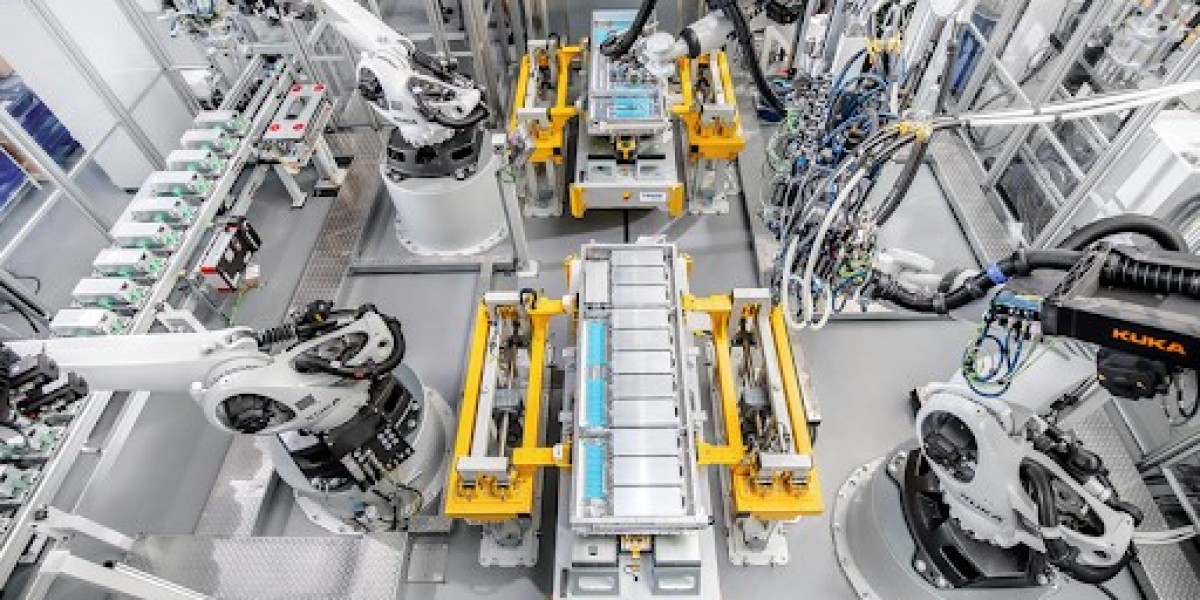

Introduction to Assembly Line Automation

Assembly line automation involves the use of technology and machinery to automate repetitive tasks in manufacturing processes. It enables businesses to increase productivity, improve product quality, and reduce costs by replacing manual labor with automated systems.

Global Adoption of Assembly Line Automation

The adoption of assembly line automation is a global phenomenon, with businesses in every corner of the world embracing automation technologies to remain competitive in today's rapidly evolving market. Countries such as China, Japan, Germany, and the United States are leading the way in automation adoption, investing heavily in robotics, artificial intelligence, and other automation technologies to drive economic growth and innovation.

Impact on Manufacturing Efficiency

Assembly line automation has a profound impact on manufacturing efficiency, enabling businesses to produce more with less. Automated systems can work around the clock, increasing production volumes and reducing cycle times. By streamlining workflows and minimizing waste, automation enhances efficiency and enables businesses to meet growing demand while maintaining profitability.

Quality Improvement

Automation plays a crucial role in ensuring consistent product quality across manufacturing operations. Automated systems can perform tasks with precision and accuracy, reducing the risk of errors and defects. By standardizing processes and implementing quality control measures, automation helps businesses deliver high-quality products that meet customer expectations and regulatory requirements.

Workforce Dynamics

The widespread adoption of assembly line automation has implications for the workforce, changing the nature of jobs and skill requirements in manufacturing. While automation may displace some low-skilled workers, it also creates new opportunities for skilled workers in areas such as robotics programming, system maintenance, and data analysis. Businesses must invest in workforce training and development to ensure that employees have the skills and knowledge needed to succeed in an increasingly automated world.

Environmental Sustainability

Automation contributes to environmental sustainability by enabling eco-friendly manufacturing practices. Automated systems can optimize resource utilization, minimize waste, and reduce energy consumption, leading to lower carbon emissions and a smaller environmental footprint. By adopting automation technologies, businesses can achieve their sustainability goals while improving efficiency and profitability.

Economic Implications

The widespread adoption of assembly line automation has significant economic implications, shaping global trade patterns and competitiveness. Countries that invest in automation technologies gain a competitive advantage in manufacturing, attracting investment, and driving economic growth. However, automation also raises concerns about job displacement and income inequality, highlighting the need for policymakers to address these challenges through education, training, and social support programs.

Challenges and Considerations

While assembly line automation offers numerous benefits, it also presents challenges and considerations that businesses must address. These include the initial investment costs, technical complexity, workforce adaptation, regulatory compliance, and cybersecurity risks. Businesses must carefully evaluate these factors and develop comprehensive strategies to mitigate risks and ensure the successful implementation of automation solutions.

Future Trends

Looking ahead, the future of assembly line automation is characterized by emerging technologies such as artificial intelligence, machine learning, and robotics. These technologies promise to further enhance automation capabilities, enabling more intelligent and adaptive manufacturing systems. Businesses that embrace these technologies and invest in continuous innovation will be well-positioned to thrive in an increasingly automated world.

Conclusion

Assembly line automation is reshaping manufacturing worldwide, driving efficiency, quality improvement, and sustainability. By embracing automation technologies and addressing challenges proactively, businesses can unlock new opportunities for growth and innovation. As automation continues to evolve, businesses must stay agile and adaptable to remain competitive in the global marketplace.