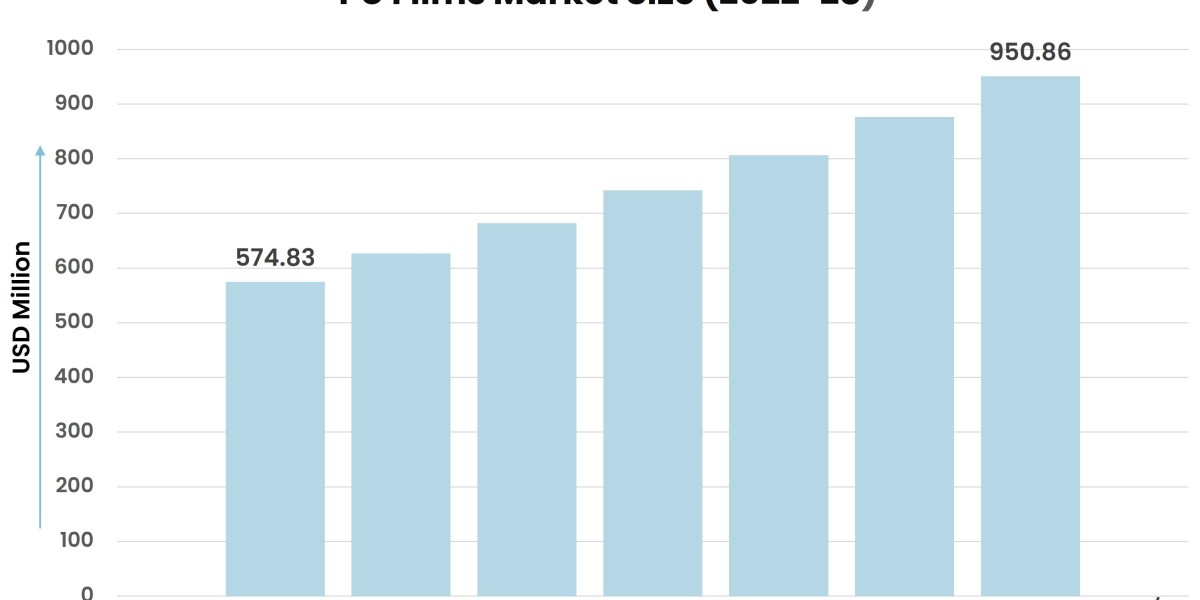

According to Stratview Research, the PU films market was estimated at USD 574.83 million in 2022 and is likely to grow at a CAGR of 8.7% during 2023-2028 to reach USD 950.86 million in 2028.

In the world of packaging and industrial applications, the realm of polyurethane (PU) films is undergoing a transformative evolution. Beyond the conventional cling wrap that many are familiar with, PU films are establishing themselves as versatile, high-performance materials with applications ranging from packaging to industrial processes. In this article, we'll delve into the dynamic PU films market, exploring the innovations that are shaping its landscape and driving its evolution.

The Basics of PU Films: Polyurethane films, commonly known as PU films, are polymer-based materials derived from the reaction of isocyanates and polyols. What sets PU films apart is their remarkable flexibility, durability, and ability to conform to various shapes. Traditionally associated with cling wrap and flexible packaging, PU films have expanded their reach into diverse industries due to their unique properties.

Versatility in Packaging: While cling wrap remains a staple in kitchens worldwide, PU films have transcended this familiar role. Manufacturers are increasingly turning to PU films for their packaging needs due to their excellent barrier properties, moisture resistance, and strength. These films offer enhanced protection for a wide range of products, including food, electronics, and pharmaceuticals, ensuring that goods reach consumers in optimal condition.

Industrial Applications: Beyond packaging, PU films are gaining prominence in industrial settings. Their exceptional durability, resistance to abrasion, and chemical inertness make them ideal for diverse applications. Industries such as automotive, construction, and textiles are leveraging PU films for purposes like surface protection, laminates, and insulation. The evolving landscape of PU films extends far beyond the kitchen, making them indispensable in a variety of manufacturing processes.

Environmental Considerations: As sustainability becomes a focal point in product development, PU films are adapting to meet eco-friendly standards. Innovations in biodegradable PU films and the use of bio-based raw materials are transforming the industry, providing environmentally conscious alternatives without compromising on performance. Beyond cling wrap, PU films are now contributing to a more sustainable future.

Technological Advancements: Advancements in manufacturing technologies are driving the evolution of PU films. Precision in production processes allows for the creation of thinner films with enhanced properties, reducing material usage and costs. Additionally, innovations in coatings and surface treatments are expanding the functionalities of PU films, opening up new possibilities for diverse applications.

Market Trends and Future Prospects: The global PU films market is experiencing steady growth, fueled by increased demand across various industries. As research and development continue to push the boundaries of what PU films can achieve, the market is expected to witness further innovation. Trends such as smart packaging, antimicrobial coatings, and the integration of PU films into emerging technologies are on the horizon, promising an exciting future for this dynamic sector.

Conclusion: In conclusion, the PU films market is evolving beyond cling wrap, embracing new applications and technologies that showcase the versatility and potential of these remarkable materials. From packaging solutions to industrial applications, the landscape of PU films is dynamic, promising continued innovation and growth. As industries seek sustainable alternatives and enhanced performance, PU films are poised to play a pivotal role in shaping the future of materials and manufacturing.