Metal surfaces are vital components in various industries, but over time, they can accumulate rust, oxides, and contaminants that compromise their integrity and performance. Traditional cleaning methods may not always suffice, leading to inefficiencies and potential damage to the metal. However, there's a solution that offers precision, efficiency, and preservation of the metal's properties – laser metal cleaning. In this blog post, we'll explore the transformative benefits of using a laser metal cleaner and how it can rejuvenate metal surfaces with ease.

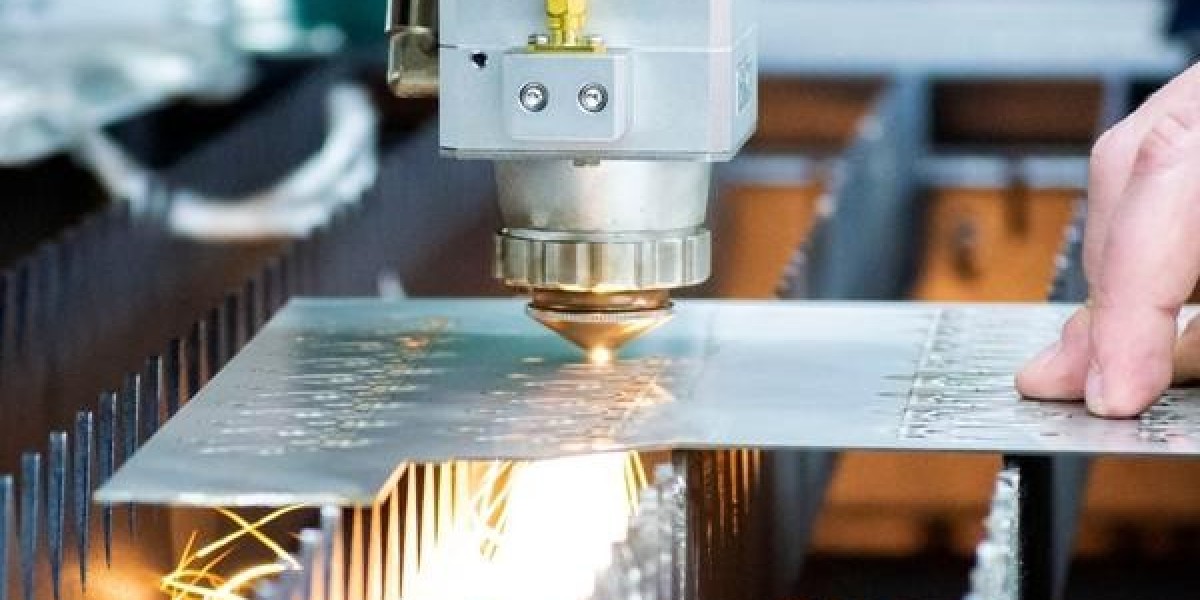

Revolutionizing Metal Cleaning: Laser metal cleaning represents a revolutionary approach to metal surface restoration. Instead of relying on abrasive methods or harsh chemicals, laser cleaning utilizes the power of focused laser beams to remove contaminants with precision and efficiency. The laser energy is absorbed by the surface contaminants, causing them to vaporize or dissociate from the metal substrate, leaving behind a clean and pristine surface. This non-contact, non-abrasive process ensures minimal impact on the metal's integrity, making it ideal for delicate or intricate components.

Precision Cleaning for Superior Results: One of the key advantages of laser metal cleaning is its ability to achieve precise and consistent results. Unlike traditional methods that may leave behind residues or cause surface damage, laser cleaning offers unparalleled control over the cleaning process. Operators can adjust parameters such as laser intensity, pulse duration, and spot size to tailor the cleaning action to the specific requirements of each application. Whether it's removing rust from automotive parts or oxides from aerospace components, laser metal cleaners deliver superior results with precision and accuracy.

Preserving Metal Properties: Another significant benefit of laser metal cleaning is its ability to preserve the properties of the metal substrate. Unlike mechanical methods such as sandblasting or grinding, which can alter the surface texture or introduce stress, laser cleaning gently removes contaminants without affecting the underlying metal. This preservation of metal properties is particularly important in industries where material integrity is critical, such as aerospace, automotive, and electronics manufacturing. With laser cleaning, operators can rejuvenate metal surfaces while maintaining their original strength, durability, and functionality.

Versatility for Various Applications: Laser metal cleaners are incredibly versatile and find applications across a wide range of industries and settings. From removing weld spatter in metal fabrication to preparing surfaces for coating or bonding in semiconductor manufacturing, laser cleaning offers a clean, efficient, and precise solution that's unmatched by traditional methods. Plus, with customizable settings and adjustable parameters, operators can tailor the cleaning process to suit the unique needs of each application, ensuring optimal results every time.

Efficiency and Cost Savings: In addition to its precision and versatility, laser metal cleaning offers significant efficiency and cost savings advantages. The non-contact nature of the process eliminates the need for consumables such as abrasives or chemicals, reducing material waste and disposal costs. Furthermore, laser cleaning can be automated and integrated into existing production lines, streamlining cleaning operations and minimizing downtime. With faster cleaning speeds and improved productivity, businesses can achieve greater efficiency and cost savings in the long run.

Environmental Friendliness: Environmental considerations are increasingly important in modern manufacturing processes, and laser metal cleaning aligns with sustainable practices. Unlike chemical cleaning methods that may generate hazardous waste or emissions, laser cleaning produces no byproducts, making it a clean and environmentally friendly solution. By reducing the use of chemicals and minimizing waste, laser metal cleaning helps businesses reduce their environmental footprint and contribute to a healthier planet.

Conclusion: In conclusion, laser metal cleaning represents a game-changing technology that offers precision, efficiency, and environmental sustainability in metal surface restoration. With its ability to achieve precise cleaning results while preserving metal properties, laser cleaning is revolutionizing metal cleaning processes across various industries. Whether it's removing rust, oxides, or contaminants, laser metal cleaners deliver superior results with unmatched precision and efficiency. Embrace the power of laser technology and transform your metal surfaces with ease and confidence.