Aluminium Extrusion Market Introduction:

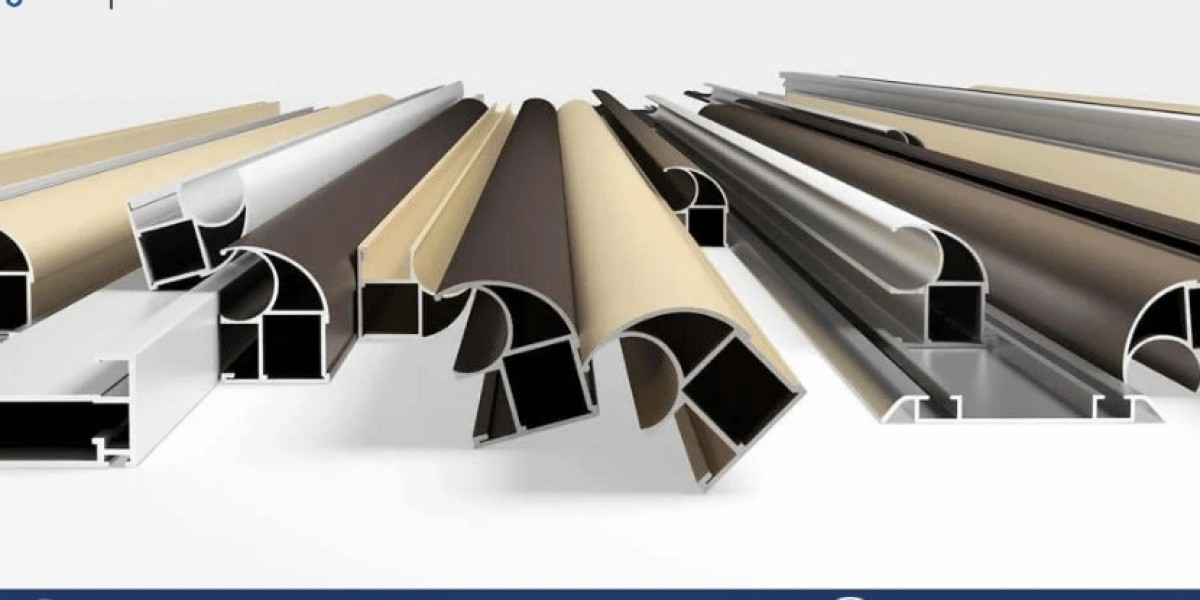

The global aluminium extrusion market size reached a volume of about 23.50 million metric tons in 2023. The industry is further expected to grow at a CAGR of about 5% between 2024 and 2032 to reach a volume of around 36.45 million metric tons by 2032. As the world grapples with the urgent need to address environmental challenges, industries are increasingly turning to sustainable practices to reduce their carbon footprint and mitigate ecological impact.

In this context, aluminium extrusions have emerged as a beacon of sustainable manufacturing, offering a myriad of environmental benefits. In this blog post, we delve deep into the environmental advantages of aluminium extrusions, exploring how this versatile material is driving positive change in modern manufacturing.

Lightweight Nature of Aluminium Extrusions:

Aluminium, known for its lightweight properties, has become the material of choice across various industries. Compared to traditional materials such as steel, aluminium extrusions offer significant weight savings without compromising on strength and durability.

This lightweight nature translates to reduced energy consumption and emissions, particularly in transportation sectors where every kilogram saved contributes to fuel efficiency and lower greenhouse gas emissions. Whether it's in automotive, aerospace, or consumer electronics, aluminium extrusions are revolutionizing product design and performance while minimizing environmental impact.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/aluminum-extrusion-market/requestsample

Recyclability and Circular Economy:

One of the most compelling environmental benefits of aluminium extrusions lies in their recyclability. Unlike many other materials, aluminium can be recycled indefinitely without losing its inherent properties. The recycling process requires only a fraction of the energy needed for primary production, making it highly energy-efficient and environmentally friendly.

By incorporating recycled aluminium into new extrusions, manufacturers can significantly reduce their reliance on virgin materials and minimize waste generation. This closed-loop approach not only conserves natural resources but also contributes to the circular economy by promoting resource efficiency and waste reduction.

Energy Efficiency in Aluminium Extrusion Process:

The aluminium extrusion process itself is inherently energy-efficient compared to other manufacturing methods. Extrusion involves forcing heated aluminium billets through a die to create complex shapes with high precision. Unlike traditional machining or casting processes that generate significant material waste and consume large amounts of energy, extrusion minimizes both raw material usage and energy consumption. Additionally, advancements in extrusion technology, such as improved heating and cooling systems, have further enhanced energy efficiency, allowing manufacturers to produce more with less environmental impact.

Reduced Material Waste:

In conventional manufacturing processes, material waste is often a significant environmental concern. However, aluminium extrusions boast remarkably low material wastage due to their precision shaping capabilities. Unlike casting or forging, which require substantial material removal to achieve the desired shape, extrusion produces near-net shapes, minimizing the need for secondary machining and reducing scrap generation.

This not only conserves raw materials but also reduces the environmental footprint associated with material extraction, processing, and disposal. By adopting aluminium extrusions, manufacturers can achieve higher material efficiency and minimize their environmental impact throughout the product lifecycle.

Environmental Impact Assessment:

Lifecycle assessments (LCAs) play a crucial role in evaluating the environmental performance of aluminium extrusions compared to alternative materials. LCAs consider the entire lifecycle of a product, from raw material extraction to end-of-life disposal, to assess its environmental impacts comprehensively.

Numerous studies have demonstrated the environmental superiority of aluminium extrusions across various metrics, including energy consumption, greenhouse gas emissions, and resource depletion. Moreover, certifications such as Leadership in Energy and Environmental Design (LEED) recognize the sustainability credentials of aluminium extrusions, incentivizing their adoption in green building projects and infrastructure development.

Challenges and Future Outlook:

Despite the numerous environmental benefits of aluminium extrusions, the industry faces several challenges that must be addressed to maximize its sustainability impact. Additionally, looking ahead, the future outlook for aluminium extrusions is influenced by various factors, including technological advancements, market trends, and regulatory developments. Let's explore the challenges and future outlook in more detail:

Challenges:

Energy Intensive Primary Production:

Primary aluminium production, which involves extracting aluminium from bauxite ore through electrolysis, is energy-intensive and contributes to greenhouse gas emissions. While advancements in technology have improved energy efficiency, reducing the carbon footprint of primary aluminium remains a significant challenge.

Recycling Infrastructure:

While aluminium is highly recyclable, the availability and accessibility of recycling infrastructure vary regionally. Limited recycling facilities and collection systems can hinder the efficient recovery and recycling of aluminium scrap, limiting its potential to reduce reliance on primary production.

Material Contamination:

Contamination of aluminium scrap with other materials, such as plastics or coatings, poses a challenge to recycling processes. Separating and purifying scrap aluminium can be costly and energy-intensive, impacting the overall environmental benefits of recycling.

Regulatory Barriers:

Regulatory frameworks and policies related to environmental standards, waste management, and emissions control can influence the adoption of sustainable practices in the aluminium extrusion industry. Compliance with evolving regulations poses challenges for manufacturers, particularly in regions with stringent environmental requirements.

Market Demand and Consumer Preferences:

The demand for aluminium extrusions is influenced by market dynamics, consumer preferences, and industry trends. Economic fluctuations, shifts in consumer behavior, and evolving market preferences for sustainable products can impact the growth and adoption of aluminium extrusions.

Future Outlook:

Technological Advancements:

Continued research and development in aluminium extrusion technology are expected to drive innovation and sustainability improvements. Advancements in alloy compositions, extrusion processes, and surface treatments can enhance the environmental performance of aluminium extrusions, reducing energy consumption and emissions.

Circular Economy Initiatives:

The transition towards a circular economy, characterized by resource efficiency and waste reduction, presents opportunities for the aluminium extrusion industry. Increased emphasis on closed-loop recycling systems, material traceability, and product lifecycle management can enhance the sustainability credentials of aluminium extrusions.

Supply Chain Collaboration:

Collaboration across the aluminium supply chain, from raw material suppliers to end-users, is essential for advancing sustainability goals. Strategic partnerships, supply chain transparency, and shared responsibility for environmental stewardship can drive collective action towards sustainable practices.

Regulatory Support:

Supportive regulatory frameworks and incentives can incentivize investments in sustainable manufacturing practices and drive industry-wide adoption of environmentally friendly technologies. Policies promoting renewable energy adoption, carbon pricing mechanisms, and extended producer responsibility programs can facilitate the transition towards a greener aluminium extrusion industry.

Consumer Awareness and Education:

Increasing consumer awareness and education about the environmental benefits of aluminium extrusions can drive demand for sustainable products and encourage manufacturers to prioritize sustainability in their operations. Marketing initiatives, eco-labeling schemes, and transparent communication about environmental performance can empower consumers to make informed purchasing decisions.

Media Contact:

Company Name: Claight Corporation

Contact Person: Louis Wane, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com