Machine embroidery is a captivating art form that allows for the creation of intricate and beautiful designs on various fabrics and materials. One of the key concepts in machine embroidery is stitch density, which plays a crucial role in determining the quality, appearance, and durability of embroidered designs. In this comprehensive guide, we'll delve into what stitch density is, its importance in machine embroidery, and how online embroidery digitizing services like ZDigitizing can help achieve optimal stitch density for your embroidery projects.

Understanding Stitch Density

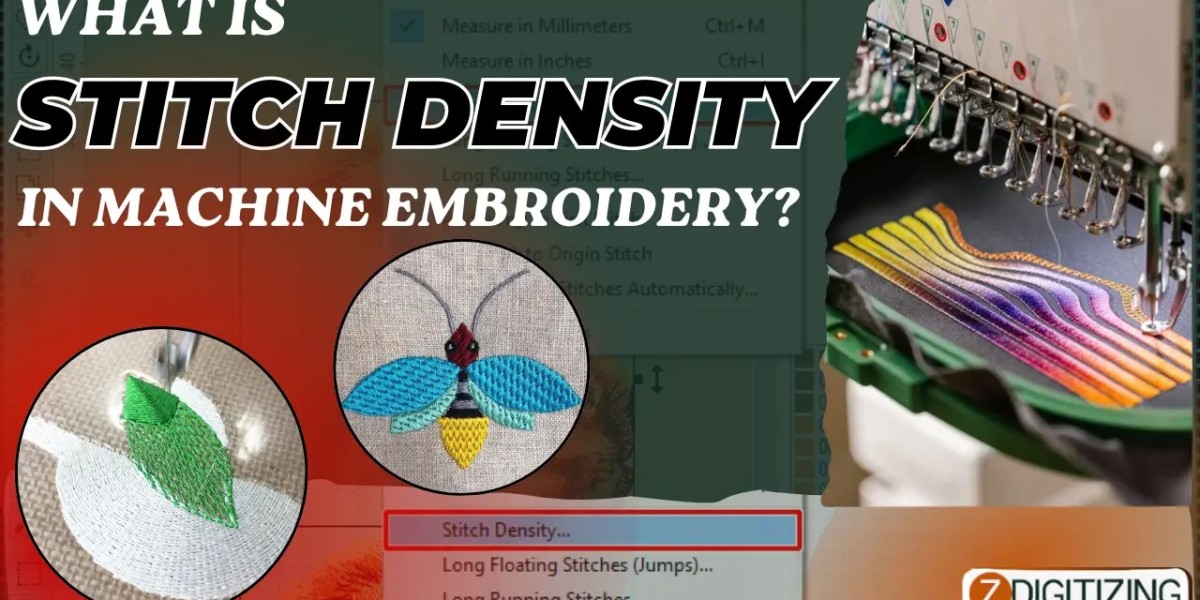

Stitch density refers to the number of stitches per unit area in an embroidered design. It measures how closely together the stitches are placed and directly impacts the overall look and feel of the embroidery. Stitch density is typically expressed in terms of stitches per inch (SPI) or stitches per centimeter (SPC), and it varies depending on factors such as the type of fabric, design complexity, and desired embroidery effect.

Importance of Stitch Density

Stitch density plays a critical role in the quality, clarity, and durability of machine embroidery. Here are some reasons why stitch density is important:

Appearance: The density of stitches affects the visual appearance of the embroidery. Optimal stitch density ensures that the design is filled evenly and completely, resulting in crisp, defined lines and vibrant colors. Too low stitch density may result in sparse, patchy embroidery, while too high stitch density may cause the design to appear bulky or distorted.

Coverage: Stitch density determines how well the fabric is covered by the digitizing embroidery thread. Proper stitch density ensures full coverage of the fabric, preventing the underlying material from showing through the stitches. This is particularly important when embroidering on thin or sheer fabrics where the base fabric is more visible.

Detail: Stitch density impacts the level of detail and intricacy that can be achieved in an embroidered design. Higher stitch density allows for finer details and smoother curves, enabling the reproduction of complex designs with precision and clarity. Lower stitch density may compromise the clarity of small details and fine lines in the design.

Durability: The density of stitches affects the durability and longevity of the embroidery. Optimal stitch density ensures that the stitches are securely anchored to the fabric, minimizing the risk of thread breakage, fraying, or unraveling over time. Properly digitized and stitched designs with optimal stitch density withstand repeated washing and wear without compromising quality.

Achieving Optimal Stitch Density

Achieving optimal stitch density requires careful consideration of various factors, including:

Fabric Type: Different fabrics require different stitch densities to achieve optimal results. Thick, dense fabrics like denim or canvas may require lower stitch density to prevent puckering or distortion, while thin, lightweight fabrics like chiffon or organza may require higher stitch density for better coverage and stability.

Design Complexity: The complexity of the design influences the required stitch density. Intricate designs with fine details may require higher stitch density to accurately reproduce the design elements, while simpler designs may require lower stitch density for a more open, airy look.

Thread Type: The type and weight of embroidery thread used also affect stitch density. Thicker threads may require lower stitch density to prevent overcrowding and distortion, while finer threads may require higher stitch density for better coverage and definition.

Machine Settings: Adjusting machine settings such as stitch length, tension, and underlay can help achieve optimal stitch density. Experimenting with different settings and conducting test stitches on scrap fabric can help determine the ideal settings for your specific embroidery project.

The Role of Online Embroidery Digitizing

Online embroidery digitizing services like ZDigitizing play a crucial role in achieving optimal stitch density for machine embroidery projects. Experienced digitizers use specialized software and techniques to convert designs into digital files that contain precise stitch data. By carefully adjusting stitch parameters such as stitch length, density, and underlay, digitizers ensure that the embroidered designs are rendered with the correct stitch density for optimal results.

ZDigitizing offers high-quality and precise embroidery digitizing services, ensuring that your designs are digitized with optimal stitch density to achieve professional-looking embroidery. Whether you're embroidering logos, monograms, or intricate designs, ZDigitizing can help bring your vision to life with perfect stitch density and clarity.

Conclusion

Stitch density is a fundamental aspect of machine embroidery that directly impacts the quality, appearance, and durability of embroidered designs. Achieving optimal stitch density requires careful consideration of various factors, including fabric type, design complexity, thread type, and machine settings. Online embroidery digitizing services like ZDigitizing play a crucial role in ensuring that designs are digitized with the correct stitch density for professional-looking embroidery results.

By understanding the importance of stitch density and leveraging the expertise of online embroidery digitizing services, you can create stunning embroidered designs that stand out and make a lasting impression.