Machine embroidery is a captivating art form that allows you to adorn fabrics with intricate designs and patterns using specialized sewing machines. One crucial aspect of successful machine embroidery is selecting the right thread weight. In this comprehensive guide, we’ll delve into the world of thread weights for machine embroidery, exploring their significance, options, and considerations. Throughout this article, we’ll incorporate relevant keywords like embroidery digitizing and zdigitizing to ensure its search engine optimization.

Understanding Thread Weight in Machine Embroidery

Thread weight refers to the thickness or diameter of the thread used in embroidery projects. It plays a pivotal role in determining the appearance, durability, and stitch quality of the final design. Thread weight is typically denoted by a number, with lower numbers indicating thicker threads and higher numbers representing finer threads.

Importance of Thread Weight in Embroidery Digitizing

Embroidery digitizing, the process of converting artwork into digital embroidery files, relies heavily on thread weight considerations. The chosen thread weight influences stitch density, tension adjustments, and overall design clarity during the digitizing process. By understanding the implications of thread weight, digitizers can optimize designs for flawless execution on embroidery machines. With fast turnaround times, competitive pricing, and a commitment to customer satisfaction, zdigitizing is your trusted partner for all your embroidery digitizing needs.

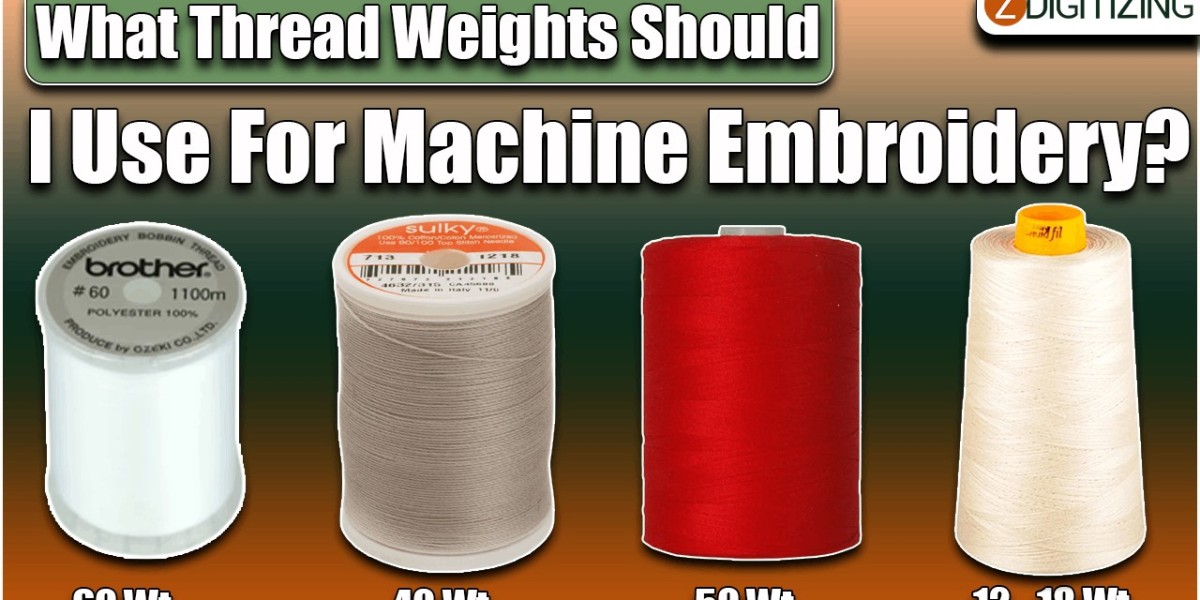

Common Thread Weights for Machine Embroidery

Machine embroidery enthusiasts have a wide range of thread weights to choose from, each offering unique characteristics and applications. Let’s explore some of the most common thread weights used in machine embroidery:

1. 40 Weight Thread

40 weight thread is one of the most versatile options for machine embroidery. With a medium thickness, it strikes a balance between coverage and detail, making it suitable for a wide range of designs. 40 weight thread is commonly used for both digitized and zDigitized embroidery projects, offering excellent stitch definition and durability.

2. 50 Weight Thread

50 weight thread is finer and lighter than 40 weight thread, making it ideal for intricate designs and small text. This thread weight produces less bulk, resulting in smoother embroidery and finer details. It’s a popular choice for delicate fabrics and projects requiring high levels of precision.

3. 60 Weight Thread

60 weight thread is exceptionally fine and lightweight, perfect for intricate and detailed embroidery work. It’s commonly used for small lettering, fine lines, and micro designs where precision is paramount. While 60 weight thread may require adjustments to tension and stitch settings, it offers unparalleled clarity and refinement in embroidery digitizing.

4. 30 Weight Thread

30 weight thread is thicker and heavier than 40 weight thread, providing enhanced coverage and texture in embroidery designs. This thread weight is well-suited for bold, textured embroidery effects, such as raised satin stitches and 3D embellishments. It’s often used for larger designs and decorative elements requiring added dimension.

Factors to Consider When Choosing Thread Weight

Selecting the appropriate thread weight for your machine embroidery project involves considering various factors to ensure optimal results. Here are some key considerations to keep in mind:

1. Fabric Type and Weight

The fabric you’re embroidering on plays a crucial role in determining the suitable thread weight. Lighter fabrics, such as silk and chiffon, may require finer thread weights to prevent puckering and distortion. Heavier fabrics, like denim and canvas, can accommodate thicker thread weights for added durability and visibility.

2. Design Complexity

The complexity of your embroidery design influences the choice of thread weight. Intricate designs with small details and fine lines may benefit from finer thread weights to maintain clarity and precision. Simpler designs or bold lettering may require thicker thread weights for enhanced visibility and coverage.

3. Desired Embroidery Effect

Consider the aesthetic effect you want to achieve with your embroidery digitizing project. Finer thread weights create subtle, delicate embroidery, while thicker thread weights produce bold, textured effects. Choose a thread weight that aligns with your desired outcome and complements the overall design aesthetic.

4. Machine Compatibility

Ensure that your embroidery machine is compatible with the chosen thread weight to avoid tension issues, thread breaks, and other stitching problems. Refer to the machine’s user manual or consult with experienced embroiderers for recommendations on compatible thread weights.

Conclusion

Selecting the appropriate thread weight is essential for achieving exceptional results in machine embroidery projects. Whether you’re digitizing intricate designs or zdigitizing detailed motifs, understanding the significance of thread weight is key to unlocking the full potential of your embroidery endeavors. By considering factors such as fabric type, design complexity, and desired embroidery effect, you can confidently choose the right thread weight to bring your creative visions to life with precision and style.