Perfluoromethylalkoxy (MFA) is a specialized fluoropolymer known for its exceptional thermal stability, chemical resistance, and unique properties. This blog delves into the dynamics of the global MFA market, examining key drivers, diverse applications across industries, emerging trends, and future growth prospects.

Understanding the MFA Market:

Perfluoromethylalkoxy (MFA) Is a type of fluoropolymer renowned for its distinct characteristics such as high thermal stability, excellent dielectric properties, chemical inertness, and low surface energy. These properties make MFA a preferred material in challenging environments across various sectors.

Market Dynamics:

Electronics and Semiconductor: MFA finds extensive use in the electronics and semiconductor industries for applications such as semiconductor manufacturing equipment components, chemical handling systems, and high-purity fluid handling due to its chemical inertness and thermal resistance.

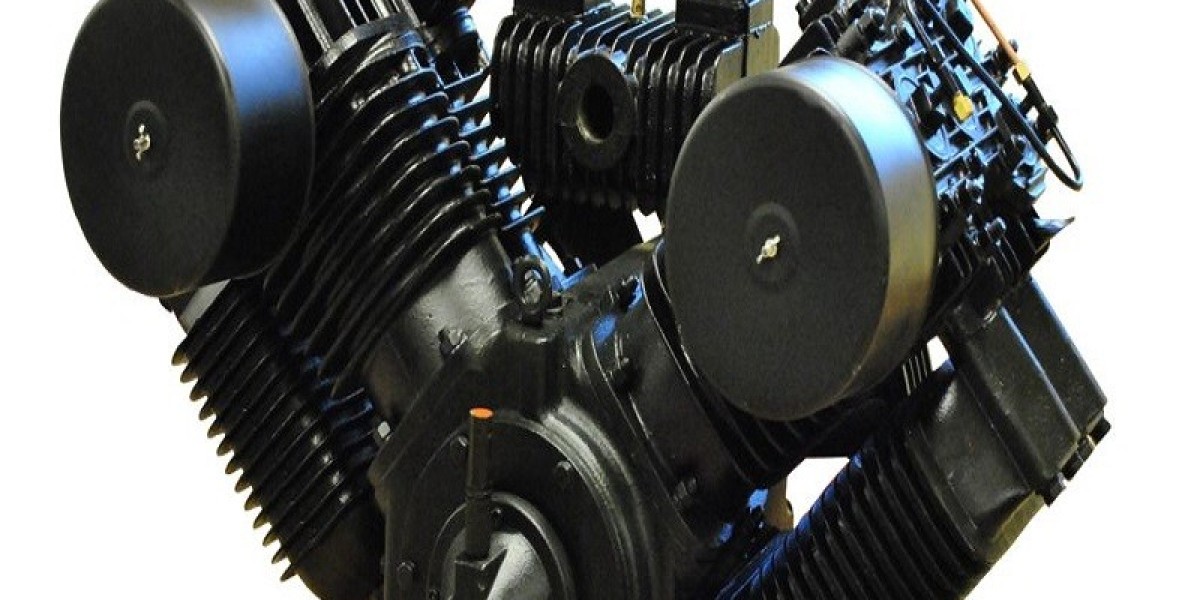

Chemical Processing: MFA's excellent resistance to corrosive chemicals, acids, and solvents makes it suitable for use in chemical processing equipment, valves, pumps, linings, and gaskets where exposure to aggressive substances is common.

Automotive and Aerospace: MFA coatings, films, and components are utilized in automotive and aerospace applications for their thermal insulation properties, anti-corrosion capabilities, and reliability in demanding operating conditions.

Healthcare and Laboratory: MFA is employed in medical and laboratory settings for components requiring high purity, chemical resistance, and biocompatibility such as tubing, fluid handling systems, and analytical equipment parts.

Applications Across Industries:

- Electronics and Semiconductor: Equipment components, chemical handling.

- Chemical Processing: Equipment linings, gaskets, valves.

- Automotive and Aerospace: Coatings, films, thermal insulation.

- Healthcare and Laboratory: Tubing, fluid handling systems, analytical equipment.

Market Trends:

Miniaturization and Precision Engineering: Increasing demand for miniaturized electronic components and precision-engineered parts in semiconductor and electronics industries drives the adoption of MFA due to its precise machining capabilities and high-performance properties.

Advanced Manufacturing Techniques: Innovations in manufacturing processes such as injection molding, extrusion, and thin-film deposition enable the production of complex MFA parts, coatings, and films, expanding application possibilities across industries.

Sustainability and Regulatory Compliance: Growing focus on sustainable materials and regulatory requirements in industries such as healthcare and automotive propel the demand for MFA as it meets stringent standards for chemical safety, environmental impact, and product performance.

Future Prospects:

The global MFA market is poised for significant growth, driven by technological advancements, increasing adoption in critical industries, and sustainability initiatives. Investments in R&D, material innovations, and market collaborations will play a pivotal role in shaping the market's evolution and unlocking new growth opportunities.

Conclusion:

Perfluoromethylalkoxy (MFA) stands out as a high-performance fluoropolymer with diverse applications in electronics, automotive, healthcare, and chemical processing industries. Understanding market trends, technological innovations, and industry requirements is crucial for stakeholders in the MFA market to harness growth opportunities effectively. With a focus on precision engineering, sustainability, and expanding application areas, the MFA market presents promising prospects for continued growth and leadership in the global polymer and materials landscape.