Automotive casting is a vital process in the manufacturing of vehicle components, offering a versatile and cost-effective method to produce complex shapes and high-strength parts. This guide explores the techniques, materials, and applications of automotive casting, providing an in-depth understanding for industry professionals and enthusiasts alike.

Techniques in Automotive Casting

1. Sand Casting

Sand casting involves creating a mold from a sand mixture, into which molten metal is poured. This technique is ideal for producing large, intricate parts and is widely used for engine blocks, cylinder heads, and transmission cases. Its flexibility and relatively low cost make it a popular choice for prototyping and small production runs.

2. Die Casting

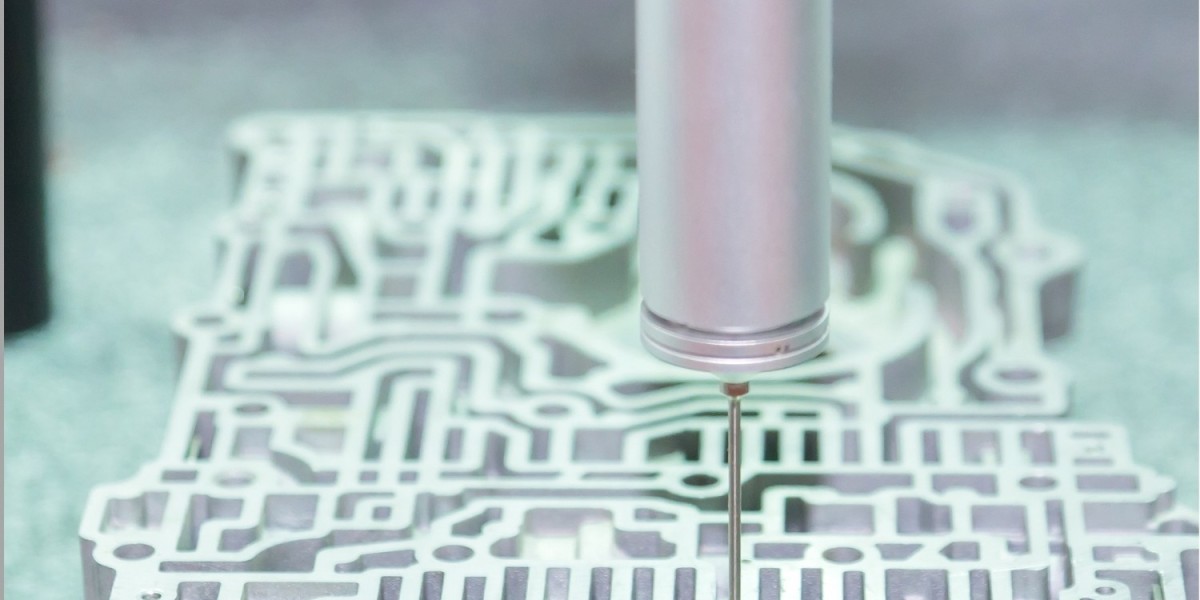

Die casting uses high-pressure to force molten metal into a steel mold, known as a die. This process is highly efficient for producing high-volume, high-precision components such as gearbox housings and engine mounts. Die casting ensures excellent surface finish and dimensional accuracy, making it suitable for complex and detailed automotive parts.

3. Investment Casting

Also known as lost-wax casting, investment casting creates parts by forming a ceramic mold around a wax pattern, which is then melted away. This technique is used for producing high-precision components with fine detail, such as turbocharger components and fuel injection parts. It is particularly advantageous for complex geometries that are difficult to machine.

4. Centrifugal Casting

In centrifugal casting, molten metal is poured into a rotating mold, creating cylindrical parts through the application of centrifugal force. This method is used for producing high-quality, dense components like brake drums and flywheels, where material integrity and uniformity are critical.

Materials Used in Automotive Casting

Aluminum Alloys Aluminum alloys are favored for their lightweight and high strength-to-weight ratio, making them ideal for engine blocks, cylinder heads, and other critical components. Their excellent thermal conductivity and resistance to corrosion further enhance their suitability for automotive applications.

Cast Iron Cast iron is renowned for its durability and wear resistance, commonly used in engine blocks, brake drums, and gearboxes. Its superior damping capacity also makes it ideal for components subjected to high stress and vibration.

Magnesium Alloys Magnesium alloys offer exceptional lightness, making them suitable for reducing vehicle weight and improving fuel efficiency. They are used in parts like transmission cases, steering components, and engine blocks, where weight reduction is a primary concern.

Steel Alloys Steel alloys provide high strength and toughness, essential for components that experience extreme stress and impact, such as crankshafts, connecting rods, and suspension parts. Their versatility and availability make them a staple in automotive casting.

Applications of Automotive Casting

Automotive casting is employed in various applications to create parts that are both functional and durable. Common applications include:

- Engine Components: Engine blocks, cylinder heads, pistons, and turbocharger housings.

- Transmission Parts: Gearbox housings, transmission cases, and clutch components.

- Chassis and Suspension: Brake drums, control arms, and steering knuckles.

- Interior and Structural Parts: Dashboards, frames, and mounting brackets.

Conclusion

Automotive casting is a crucial process in vehicle manufacturing, offering a range of techniques and materials to produce high-quality, intricate parts. Understanding the various methods and their applications helps manufacturers choose the best approach for their specific needs, ensuring efficiency, cost-effectiveness, and superior performance in their vehicles. Whether for mass production or specialized components, automotive casting remains a cornerstone of the automotive industry.