Bearing pullers are essential tools in the maintenance and repair of machinery. They simplify the task of removing bearings, ensuring the integrity of the bearing and the machinery. Two common types are heavy-duty bearing pullers and axle bearing pullers. This article delves into their applications, types, and selection criteria, providing an in-depth understanding for professionals in the field.

Understanding Bearing Pullers

Bearing pullers are mechanical tools designed to remove bearings from machinery. They are indispensable in industries ranging from automotive to industrial manufacturing. Their primary function is to extract bearings without causing damage to the machinery or the bearings themselves.

Types of Bearing Pullers

- External Bearing Pullers: These pullers are used to remove bearings that are seated on a shaft. They grip the outer race of the bearing and pull it off the shaft.

- Internal Bearing Pullers: These are designed to remove bearings that are seated within a housing. They grip the inner race and pull the bearing out of its housing.

- Slide Hammer Pullers: These are used for bearings that are particularly tight or difficult to remove. They use a sliding hammer action to apply impact force, making them effective for stubborn bearings.

Heavy-Duty Bearing Pullers

Heavy-duty bearing puller are robust tools designed for removing large and heavy bearings. These pullers are typically used in industrial settings where bearings are substantial and require significant force to remove.

Applications of Heavy-Duty Bearing Pullers

- Industrial Machinery: Used extensively in the maintenance of heavy machinery in manufacturing plants.

- Construction Equipment: Essential for the upkeep of large construction machinery such as excavators and bulldozers.

- Marine Equipment: Critical for maintaining large marine engines and related equipment.

Features of Heavy-Duty Bearing Pullers

- High Load Capacity: Capable of handling the removal of very large bearings.

- Durable Construction: Made from high-strength materials to withstand significant forces.

- Adjustable Arms: Feature adjustable arms to accommodate bearings of different sizes.

- Hydraulic Assistance: Many heavy-duty pullers incorporate hydraulic systems to provide the necessary force with minimal manual effort.

Axle Bearing Pullers

Axle bearing pullers are specialized tools designed for removing bearings from axles. These are particularly common in automotive repair and maintenance.

Applications of Axle Bearing Pullers

- Automotive Repair: Used in the repair and maintenance of cars, trucks, and other vehicles.

- Agricultural Equipment: Essential for the maintenance of tractors and other agricultural machinery.

- Heavy Vehicles: Important for the maintenance of trucks, buses, and other heavy vehicles.

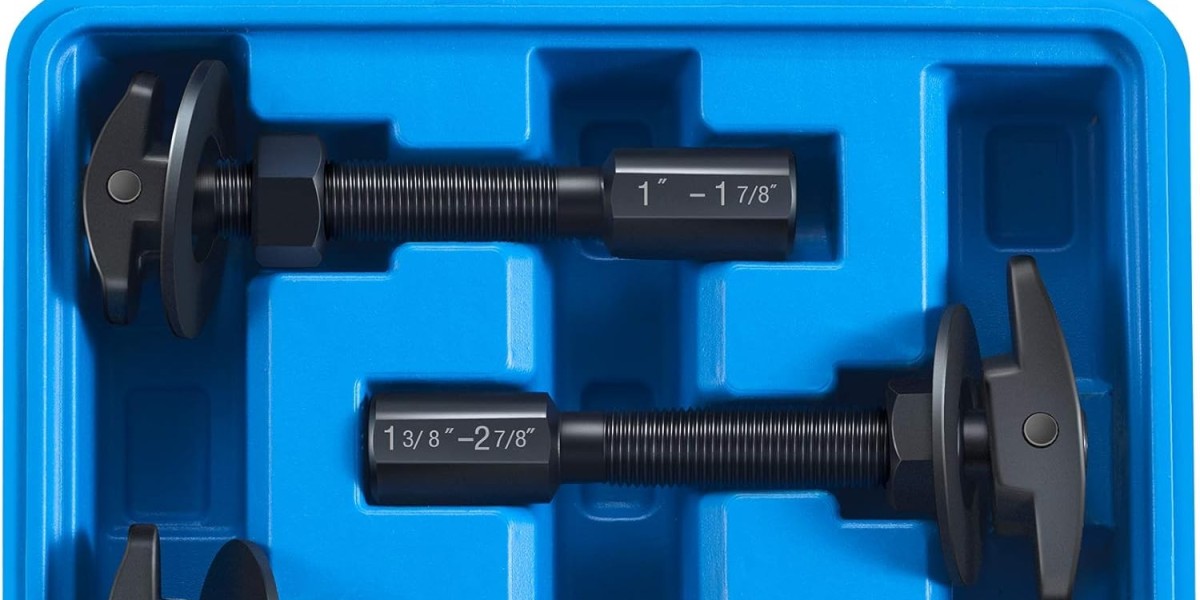

Features of Axle Bearing Pullers

- Precision Fit: Designed to fit the specific bearings found on axles.

- Ease of Use: Engineered to be user-friendly, allowing for quick and efficient bearing removal.

- Compatibility: Compatible with a wide range of axle sizes and types.

- Durability: Built to last, even with frequent use.

Selecting the Right Bearing Puller

Choosing the right bearing puller is crucial for efficient and safe bearing removal. Here are some factors to consider:

Load Capacity

The load capacity of the bearing puller must be sufficient to handle the size and weight of the bearings you need to remove. Heavy-duty pullers are necessary for large industrial bearings, while smaller pullers are suitable for automotive applications.

Adjustable arms are important for accommodating bearings of various sizes. Ensure the puller can adjust to the specific dimensions of the bearings you will be working with.

Hydraulic Assistance

Hydraulic pullers are beneficial for heavy-duty applications as they reduce the manual effort required and provide greater pulling force. If you frequently work with large bearings, a hydraulic puller is a wise investment.

Build Quality

The build quality of the puller is essential for durability and safety. Look for pullers made from high-strength materials such as steel. A well-built puller will last longer and be more reliable.

Consider how easy the puller is to use. Features such as ergonomic handles, quick-release mechanisms, and clear instructions can make a significant difference in usability.

Maintenance and Safety

Proper maintenance and safety practices are vital when using bearing pullers. Here are some tips to ensure safe and effective use:

Inspect your Axle bearing puller regularly for signs of wear or damage. Replace any worn or damaged parts immediately to prevent accidents and ensure efficient operation.

Cleanliness

Keep your pullers clean and free from debris. Dirt and grime can affect the performance of the puller and lead to premature wear.

Lubricate moving parts regularly to ensure smooth operation. This is especially important for hydraulic pullers, as proper lubrication can prevent leaks and maintain hydraulic pressure.

Safety Gear

Always wear appropriate safety gear, including gloves and safety glasses, when using bearing pullers. This protects you from injuries caused by flying debris or accidental slips.

Always follow the manufacturer’s instructions for use. Incorrect usage can lead to damaged equipment and serious injury.

Conclusion:

Heavy-duty bearing pullers and axle bearing pullers are indispensable tools in various industries, from automotive repair to industrial maintenance. Understanding their applications, features, and selection criteria ensures that you choose the right tool for your needs and use it safely and effectively.