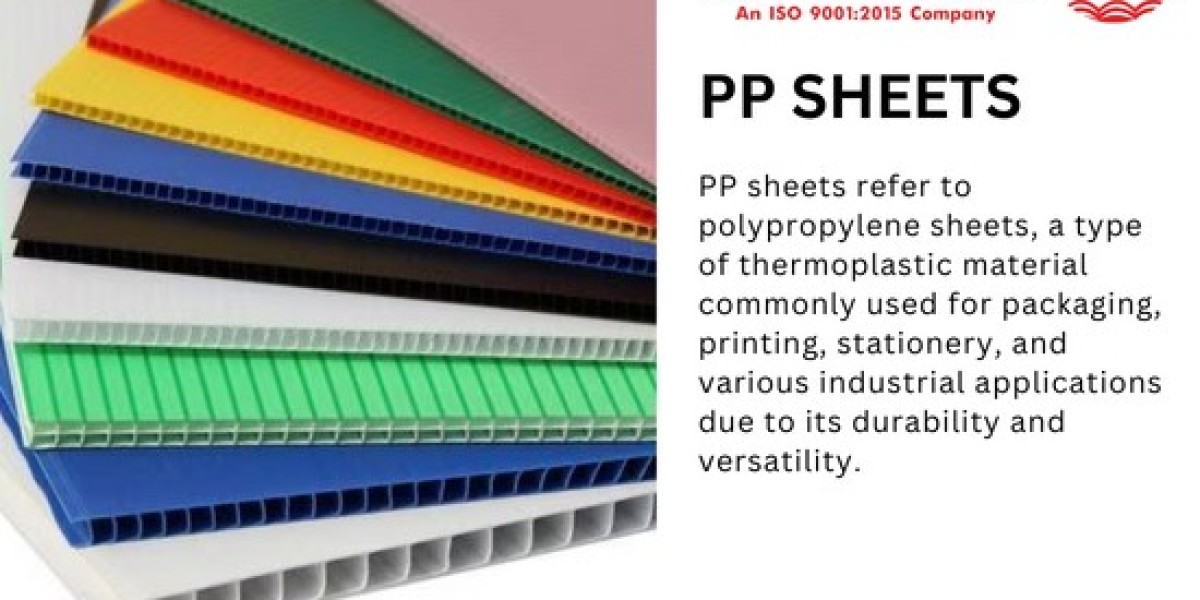

Polypropylene (PP) sheet is a versatile plastic material that is widely used in various industries due to its excellent properties and adaptability. PP Hollow Sheet Price This thermoplastic polymer is known for its toughness, chemical resistance, and ease of fabrication. Whether in packaging, automotive, or medical applications, PP sheets have become a material of choice for many manufacturers and engineers.

Properties of PP Sheet

PP Sheet Manufacturer exhibit a range of beneficial properties:

Chemical Resistance: Polypropylene is highly resistant to a variety of chemicals, making it ideal for containers and components that come into contact with aggressive substances.

Durability: The material is known for its toughness and ability to withstand significant wear and tear.

Lightweight: Despite its strength, PP is relatively lightweight, which is advantageous in applications where weight reduction is essential.

Thermal Resistance: It maintains stability over a wide temperature range, making it suitable for various thermal environments.

Moisture Resistance: PP does not absorb water, making it suitable for moisture-prone applications.

Recyclability: Polypropylene is recyclable, contributing to sustainable practices in manufacturing.

Applications of PP Sheet

Packaging: PP Sheets Manufacturer are extensively used in the packaging industry for creating containers, boxes, and trays. Their chemical resistance and durability ensure the safe transportation and storage of goods.

Automotive Industry: In the automotive sector, PP sheets are used for interior trim, battery cases, and other components due to their durability and resistance to impact and chemicals.

Construction: PP sheets find applications in the construction industry for producing materials such as wall panels, flooring, and roofing due to their moisture and chemical resistance.

Medical Field: The medical industry utilizes PP sheets for items such as sterilization trays, medical device components, and laboratory containers because they can be easily sterilized and are chemically inert.

Stationery Products: Items like folders, binders, and other office supplies are often made from PP sheets due to their durability and ease of customization.

Signage and Display: PP sheets are used for producing signs, displays, and exhibition boards due to their printability and lightweight nature.

Benefits of Using PP Sheet

Cost-Effectiveness: PP sheets offer an economical solution for many applications, combining affordability with a long lifespan.

Versatility: The wide range of properties makes PP sheets suitable for a myriad of uses across different industries.

Ease of Processing: PP sheets can be easily fabricated, welded, and molded, providing flexibility in manufacturing processes.

Environmental Impact: Being recyclable, PP sheets contribute to reducing plastic waste and promoting sustainability.

Aesthetic Flexibility: PP sheets can be produced in various colors and finishes, allowing for aesthetic customization.

Conclusion

Polypropylene (PP) sheets are a vital material in numerous industries due to their exceptional properties and versatility. Their applications range from packaging and automotive to medical and construction, highlighting their adaptability and utility. Understanding the benefits and common questions about PP sheets can help in selecting the right material for specific needs, ensuring efficiency and effectiveness in various applications. With their recyclability and durability, PP sheets not only offer practical advantages but also support environmental sustainability.

Frequently Asked Questions (FAQs)

Q1: What is a PP sheet made from?

A1: A PP sheet is made from polypropylene, a thermoplastic polymer that is synthesized from propylene monomers. It is known for its toughness, chemical resistance, and versatility.

Q2: How are PP sheets manufactured?

A2: PP sheets are typically manufactured through a process called extrusion, where polypropylene pellets are melted and then formed into sheets using an extruder. The sheets are then cooled and cut to the desired size.

Q3: Can PP sheets be recycled?

A3: Yes, PP sheets are recyclable. They can be reprocessed and used to manufacture new products, contributing to environmental sustainability.

Q4: Are PP sheets safe for food contact?

A4: PP sheets are generally safe for food contact. They are commonly used in the food packaging industry due to their chemical inertness and resistance to moisture.

Q5: What are the temperature limits for PP sheets?

A5: PP sheets can withstand temperatures up to approximately 100°C (212°F) without deforming. They maintain their properties in both low and high-temperature environments.