The electric vehicle (EV) adhesives market is poised for significant growth and innovation as the global automotive industry undergoes a transformation towards electrification. Adhesives play a crucial role in enhancing the performance, safety, and sustainability of electric vehicles, making them a key component in the EV manufacturing process. This article explores the future of electric vehicle adhesives, providing insights and projections for this dynamic market.

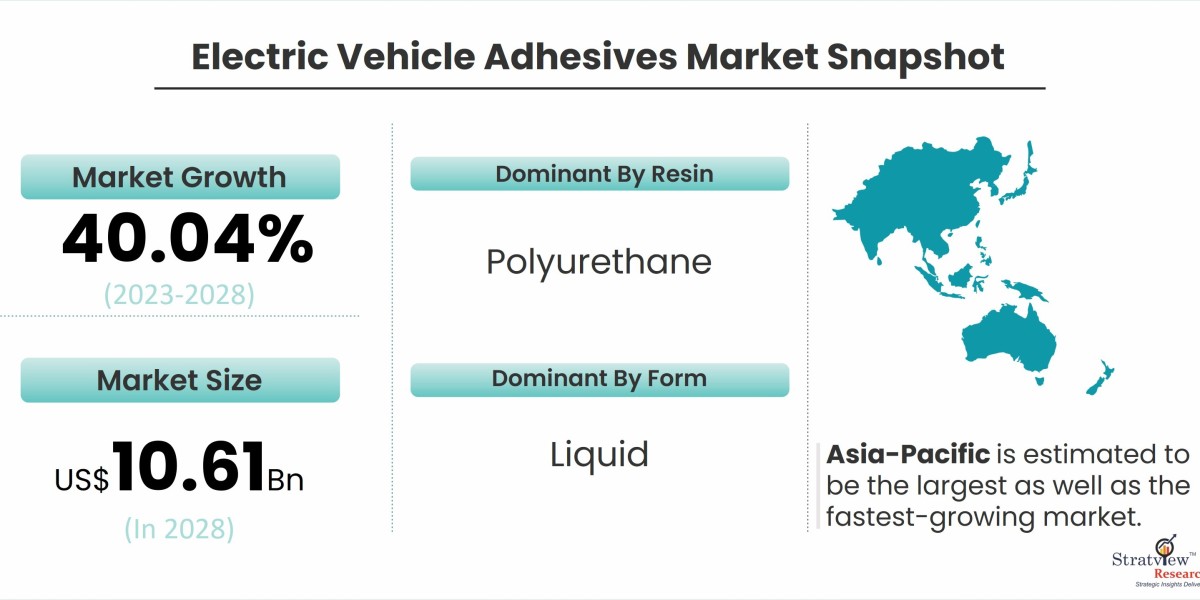

According to Stratview Research, the electric vehicle adhesives market was estimated at USD 1.38 billion in 2022 and is likely to grow at a CAGR of 40.04% during 2023-2028 to reach USD 10.61 billion in 2028.

Market Growth Drivers

The demand for electric vehicles is rising rapidly, driven by government regulations aimed at reducing greenhouse gas emissions, advancements in battery technology, and increasing consumer interest in sustainable transportation. As automakers accelerate their electrification efforts, the demand for adhesives used in electric vehicle assembly, particularly in battery pack manufacturing and lightweighting initiatives, is expected to grow substantially.

Technological Advancements

Future advancements in adhesive technologies will focus on improving bonding strength, durability, and resistance to temperature extremes, vibrations, and moisture. Innovations in hybrid bonding techniques, which combine adhesives with mechanical fasteners, will become more prevalent to ensure optimal structural integrity and flexibility in electric vehicle design.

Lightweighting and Performance Enhancement

Adhesives will continue to play a critical role in lightweighting strategies for electric vehicles. By bonding lightweight materials such as aluminum, composites, and high-strength steel, adhesives contribute to reducing the overall weight of EVs. This not only enhances energy efficiency and extends driving range but also improves vehicle dynamics and performance.

Environmental Sustainability

Sustainability will remain a key driver in the development of electric vehicle adhesives. Manufacturers are expected to focus on reducing volatile organic compound (VOC) emissions and adopting more eco-friendly formulations to comply with stringent environmental regulations. Adhesives enable the use of lightweight materials and contribute to overall vehicle efficiency, supporting the automotive industry's transition towards a more sustainable future.

Regional Market Expansion

The electric vehicle market is expanding globally, with significant growth expected in regions such as Asia-Pacific, Europe, and North America. Adhesive manufacturers are likely to expand their production capacities and establish strategic partnerships to meet the growing demand from electric vehicle manufacturers in these regions.

Conclusion

In conclusion, the future of electric vehicle adhesives looks promising, driven by the increasing adoption of electric vehicles, advancements in adhesive technologies, lightweighting initiatives, sustainability requirements, and regional market expansion. Adhesive manufacturers and suppliers are well-positioned to capitalize on these opportunities by developing innovative solutions that address the unique challenges and demands of electric vehicle manufacturing. As the automotive industry continues to evolve, electric vehicle adhesives will play a pivotal role in shaping the future of transportation towards cleaner and more sustainable mobility solutions.