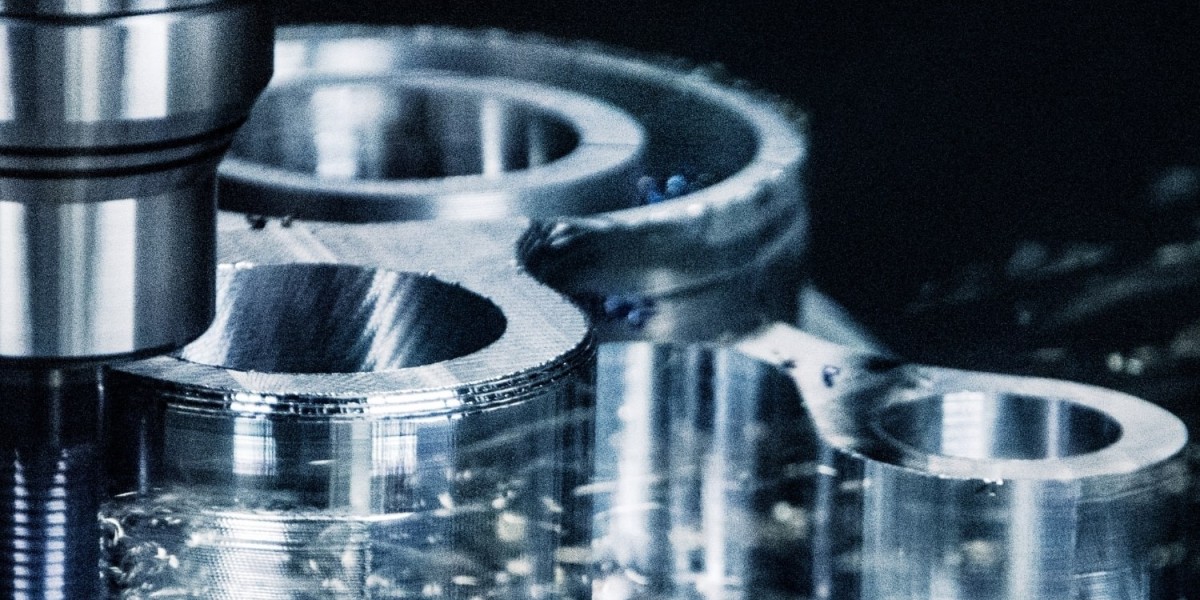

Steel machining is a fundamental process in the manufacturing industry, enabling the creation of intricate and durable steel components used in various applications. This comprehensive guide aims to provide a detailed overview of steel machining, exploring the techniques, tools, and considerations involved in the process. From milling and turning to grinding and drilling, understanding steel machining is essential for engineers, manufacturers, and metalworking enthusiasts.

Importance of Steel Machining:

Steel is a widely used material due to its exceptional strength, versatility, and durability. Steel machining allows manufacturers to transform raw steel into precise components that meet specific design requirements. From automotive parts to industrial machinery, steel machining plays a critical role in various industries, enabling the production of high-quality, functional, and reliable products.Machining Techniques:

a. Milling: Milling is a versatile machining technique that involves rotating a cutting tool with multiple teeth to remove material from the workpiece. It can be performed on various types of milling machines, including vertical mills, horizontal mills, and CNC mills. Milling is used to create complex shapes, slots, contours, and threads on steel components.

b. Turning: Turning is a machining technique used to create cylindrical components. It involves rotating the workpiece while a cutting tool removes material from the outer surface. Turning operations, performed on lathes or CNC turning machines, can produce features like diameters, tapers, grooves, and threads on steel parts.

c. Grinding: Grinding is a precision machining process used to achieve tight tolerances and excellent surface finishes. It involves using abrasive wheels to remove material and achieve the desired shape and surface quality. Grinding is commonly used for finishing operations on steel components, delivering high precision and exceptional surface integrity.

d. Drilling: Drilling involves creating holes in steel components using rotary cutting tools called drills. The drilling process can be performed manually or with the assistance of CNC drilling machines. Various drill types, such as twist drills, step drills, or indexable drills, are used to produce holes of different sizes and depths in steel parts.

Tooling and Cutting Parameters:

Successful steel machining relies on choosing the right tools and optimizing cutting parameters. High-speed steel (HSS) and carbide tools are commonly used for steel machining due to their hardness and wear resistance. Factors such as cutting speed, feed rate, and depth of cut must be properly selected to achieve efficient material removal, minimize tool wear, and ensure dimensional accuracy.Workholding and Fixturing:

Secure workholding is crucial for accurate and safe steel machining. Workpieces need to be properly clamped or fixtured to withstand cutting forces and prevent vibrations. Common workholding methods include vices, chucks, collets, and fixtures specifically designed for steel machining operations. Proper workpiece setup ensures stability, precision, and repeatability throughout the machining process.Surface Treatments and Finishing:

After machining, steel components might undergo surface treatments and finishing operations to enhance their properties and aesthetics. These treatments include heat treatment processes like hardening, tempering, or case hardening, as well as surface coatings or plating to improve corrosion resistance or provide decorative finishes.

Conclusion:

Steel machining is a critical process in the manufacturing industry, enabling the creation of precise and durable steel components. By utilizing techniques such as milling, turning, grinding, and drilling, manufacturers can transform raw steel into functional parts for various applications. Choosing the right tools, optimizing cutting parameters, ensuring proper workholding, and considering surface treatments and finishing operations are essential for achieving high-quality steel machined components. With a solid understanding of steel machining principles, engineers and manufacturers can unleash the full potential of steel, delivering reliable and innovative solutions across different industries.