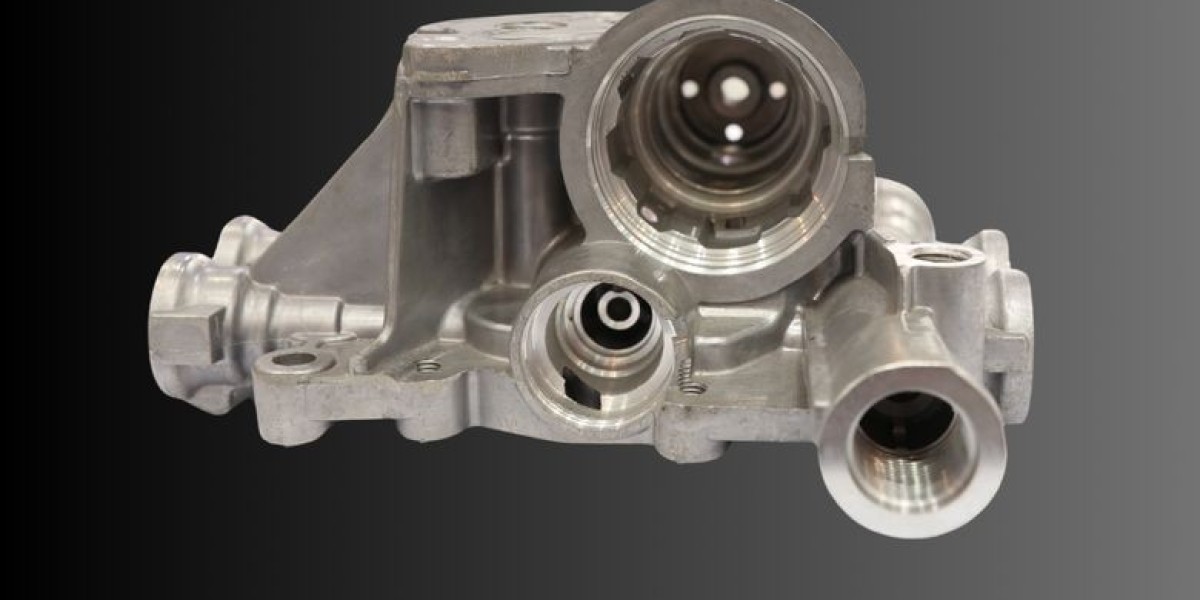

Machined castings, a harmonious blend of casting and machining, represent a powerful approach to creating complex and precise metal components. This guide delves into the world of machined casting, exploring the process, its advantages, the types of castings involved, and the diverse applications that make it an indispensable technique in various industries.

1. The Art of Combining Casting and Machining:

Machined castings involve a two-step process:

- Casting: Molten metal is poured into a mold, solidifying into a rough shape known as a casting. This process is versatile, allowing for the creation of complex geometries and intricate designs.

- Machining: The casting is then subjected to machining operations, using cutting tools to remove material and achieve precise dimensions, surface finishes, and intricate details.

2. The Advantages of Machined Castings:

Machined castings offer a unique combination of benefits:

- Cost-Effectiveness: Casting is a cost-effective way to create complex shapes, while machining allows for precise finishing and customization.

- Versatility: Machined castings can be used to create a wide range of components, from simple to highly complex, with various materials and designs.

- Strength and Durability: Castings offer high strength and durability, while machining can enhance these properties by creating specific features and surface finishes.

- Production Efficiency: Machined castings can be produced in large quantities, making them suitable for mass production applications.

3. The Types of Castings Involved:

Various types of castings can be machined, each with its own unique properties:

- Gray Iron Castings: The most common type, known for their strength, wear resistance, and cost-effectiveness.

- Ductile Iron Castings: Offer higher strength and ductility compared to gray iron, making them suitable for demanding applications.

- Steel Castings: Provide high strength, toughness, and wear resistance, making them ideal for structural components and demanding applications.

- Aluminum Castings: Lightweight, corrosion-resistant, and easily machinable, making them suitable for various applications, including automotive and aerospace.

4. The Machining Process: Shaping Precision and Detail:

Machining operations are performed using various tools and techniques:

- Turning: Removing material from a rotating workpiece to create cylindrical shapes, diameters, and tapers.

- Milling: Using a rotating cutter with multiple teeth to remove material from a workpiece, creating flat surfaces, grooves, and other features.

- Drilling: Creating holes in a workpiece using a rotating drill bit.

- Boring: Enlarging existing holes or creating precise cylindrical cavities.

- Reaming: Enlarging and smoothing existing holes to precise dimensions.

- Tapping: Creating internal threads in a workpiece using a rotating tap.

5. The Applications of Machined Castings:

Machined castings are widely used in various industries, including:

- Automotive: Engine blocks, cylinder heads, transmission housings, and other components.

- Aerospace: Aircraft components, engine parts, and other structural components.

- Construction: Manhole covers, pipes, valves, and other infrastructure components.

- Industrial Machinery: Gears, shafts, housings, and other components for various industrial machines.

- Consumer Goods: Electronics, appliances, and other consumer products.

6. The Future of Machined Castings:

The future of machined castings is driven by advancements in casting and machining technologies:

- Advanced Casting Processes: New casting processes, such as investment casting and 3D printing, are enabling the creation of more complex and intricate castings.

- High-Speed Machining: Innovations in machining technology, such as high-speed machining and CNC machining, are increasing the speed and precision of machining operations.

- Automation: The increasing use of automation in manufacturing is leading to the development of robotic systems that can perform machining operations with greater accuracy and efficiency.

Conclusion:

Machined castings represent a powerful combination of casting and machining, offering a cost-effective and versatile approach to creating complex and precise metal components. The process of machined casting continues to evolve, driven by technological advancements, ensuring its enduring relevance in the world of manufacturing and engineering.