Extruded Polystyrene (XPS) is a key player in the modern insulation market, renowned for its exceptional properties and wide range of applications. As the demand for energy-efficient and sustainable building materials continues to rise, Extruded Polystyrene stands out as an indispensable component in construction and infrastructure projects.

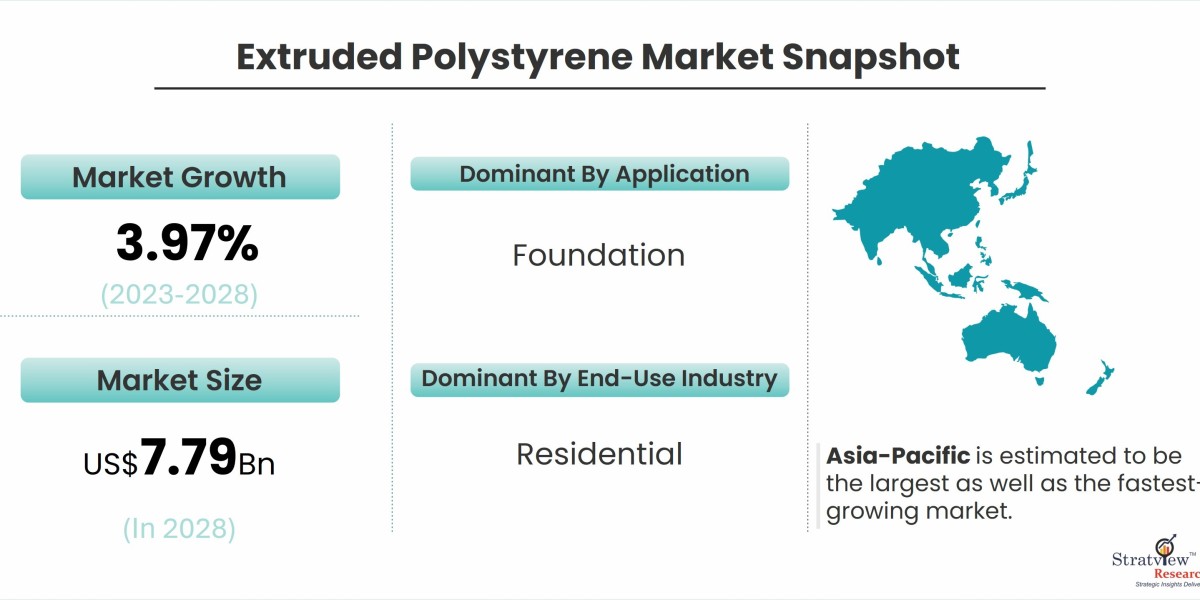

According to Stratview Research, the extruded polystyrene market was estimated at USD 6.15 billion in 2022 and is likely to grow at a CAGR of 3.97% during 2023-2028 to reach USD 7.79 billion in 2028.

Superior Insulation Properties

One of the primary reasons Extruded Polystyrene is the backbone of modern insulation solutions is its superior thermal insulation properties. Extruded Polystyrene is a closed-cell foam, which means its structure consists of tightly packed cells that prevent air and moisture from penetrating. This structure gives XPS a high thermal resistance (R-value), making it an excellent insulator against heat loss and gain. Buildings insulated with Extruded Polystyrene can maintain more stable indoor temperatures, reducing the need for heating and cooling and leading to significant energy savings.

Durability and Strength

Extruded Polystyrene is also highly durable and strong, making it suitable for various applications that require long-lasting performance. It is resistant to water absorption, which prevents degradation over time and maintains its insulating properties even in wet conditions. This durability makes Extruded Polystyrene ideal for use in foundations, walls, roofs, and below-grade applications where moisture resistance is crucial. Its compressive strength also supports heavy loads, making it suitable for under slab insulation in commercial and industrial buildings.

Sustainability and Environmental Impact

In the current era of sustainable construction, Extruded Polystyrene plays a vital role. Its long lifespan and energy-saving capabilities contribute to a reduction in the overall carbon footprint of buildings. Additionally, many manufacturers are adopting environmentally friendly practices in the production of Extruded Polystyrene, such as using recycled materials and reducing greenhouse gas emissions during manufacturing. The recyclability of Extruded Polystyrene at the end of its life cycle further enhances its sustainability profile.

Versatile Applications

Extruded Polystyrene is incredibly versatile, finding applications in various sectors beyond traditional building insulation. In the construction industry, it is used in cavity walls, floors, flat roofs, and external wall insulation systems. It is also employed in infrastructure projects, such as roads and railways, to provide frost protection and stabilize the ground. In the packaging industry, Extruded Polystyrene is used to protect fragile items due to its shock-absorbing properties.

Conclusion

Extruded Polystyrene has established itself as a cornerstone of modern insulation solutions due to its exceptional thermal performance, durability, and versatility. As the construction industry continues to evolve, the demand for high-quality, energy-efficient, and sustainable insulation materials will only increase. Extruded Polystyrene, with its proven track record and innovative advancements, is poised to remain at the forefront of this growth, underpinning the development of more sustainable and efficient buildings worldwide.

By integrating Extruded Polystyrene into construction projects, builders and architects can ensure superior insulation, energy savings, and long-term performance, making it an essential material in the pursuit of sustainable building practices.