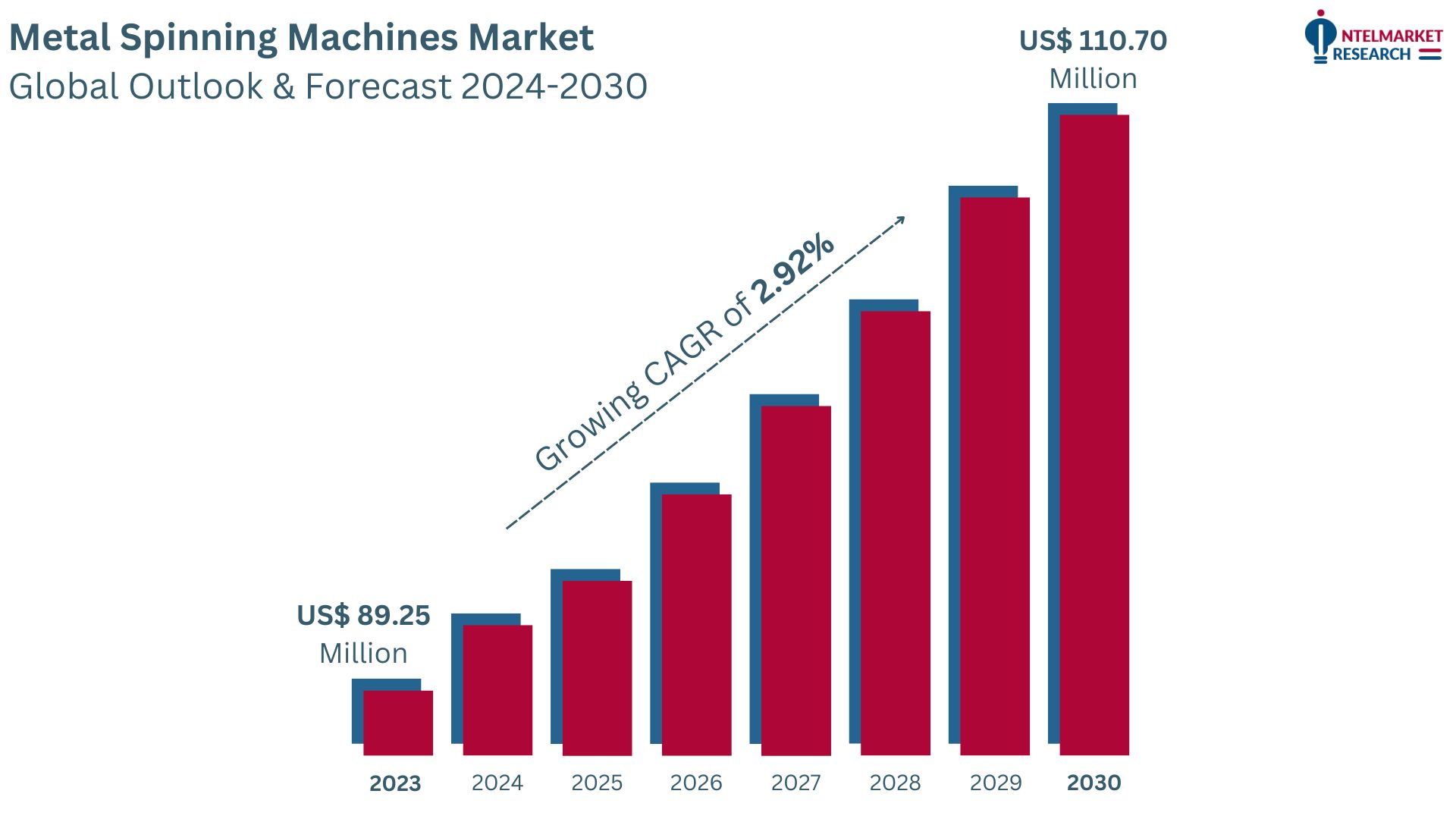

The global Metal Spinning Machines market exhibited a robust performance, registering a valuation of US$ 89.25 million in 2023. Forecasts project a steady growth trajectory, with an anticipated surge to US$ 110.70 million by 2030. This represents a Compound Annual Growth Rate (CAGR) of 2.92% during the forecast period spanning 2024 to 2030.

- Table of Contents

- List of Tables & Figures

- Charts

- Research Methodology

Get FREE Sample of this Report at https://www.intelmarketresearch.com/download-free-sample/168/metal-spinning-machines

Major Global Manufacturers

The Metal Spinning Machines market is dominated by key players, with notable contributions from industry leaders. In 2023, two prominent manufacturers were Leifeld Metal Spinning and WF Maschinenbau und Blechformtechnik. These companies played a pivotal role in shaping the market landscape.

Leifeld Metal Spinning:

- Market Presence: Leifeld Metal Spinning is a prominent player, holding a substantial market share in 2023.

- Technological Leadership: Renowned for its cutting-edge technology, Leifeld Metal Spinning continually invests in research and development, staying at the forefront of innovation.

- Diversified Product Portfolio: The company's extensive range of metal spinning machines caters to various industries, contributing to its revenue growth.

WF Maschinenbau und Blechformtechnik:

- Strategic Market Positioning: WF Maschinenbau und Blechformtechnik secured a noteworthy position in the market, leveraging strategic initiatives and market understanding.

- Global Reach: The company's global reach and strong distribution network enabled it to capture a significant market share.

- Customer-Centric Approach: WF Maschinenbau und Blechformtechnik's customer-centric approach, with a focus on tailored solutions, contributed to its success.

Market Concentration and Revenue Distribution

In 2023, the market exhibited a concentration among the top three vendors, which collectively accounted for approximately 29% of the total revenue. This highlights the competitive dynamics within the Metal Spinning Machines market and the significant influence these major players wield.

This report aims to provide a comprehensive presentation of the global market for Metal Spinning Machines, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Metal Spinning Machines.

The Metal Spinning Machines market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Metal Spinning Machines market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Metal Spinning Machines manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, Sales, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation

By Company

- Leifeld Metal Spinning

- WF Maschinenbau und Blechformtechnik

- Industrias Puigjaner

- MJC Engineering and Technology

- Abacus Maschinenbau

- Daitoh Spinning

- Ernst Grob

- Repkon Machine

- Grotnes

- Nova Sidera

- Guangdong Prosper

- Quanzhou Taida

- Shanghai Okay

Segment by Type

- Single Roller

- Double Roller

- Others

Segment by Application

- Automotive

- General Industrial

- Defence

- Energy

- Others

Sales by Region

- North America

- U.S.

- Canada

- Mexico

- Asia-Pacific

- China

- Japan

- Southeast Asia

- India

- Others

- Europe

- Germany

- France

- U.K.

- Italy

- Russia

- Others

- South America

- Brazil

- Argentina

- Others

- Mideast & Africa

key trends in the metal spinning machines market:

Automation and digitalization: Manufacturers are increasingly adopting automated and digitalized metal spinning machines to improve efficiency, precision, and consistency in the production process. Computer-controlled and CNC (Computer Numerical Control) metal spinning machines are gaining popularity, enabling better control, repeatability, and reduced human intervention.

Demand for lightweight materials: The automotive and aerospace industries are driving the demand for lightweight materials to improve fuel efficiency and reduce emissions. Metal spinning machines capable of processing lightweight materials, such as aluminum, titanium, and advanced alloys, are in high demand to produce components with complex geometries and high strength-to-weight ratios.

Emphasis on precision and quality: As industries strive for tighter tolerances and higher quality standards, there is a growing demand for metal spinning machines that can deliver precise and consistent results. Manufacturers are investing in advanced technologies, such as specialized tooling, sensors, and monitoring systems, to enhance the accuracy and repeatability of the metal spinning process.

Customization and versatility: With the increasing demand for customized and unique products, manufacturers are seeking metal spinning machines that offer flexibility and versatility. Machines with quick changeover capabilities and the ability to handle a wide range of materials and part sizes are becoming more attractive to cater to diverse customer requirements.

Energy efficiency and sustainability: In line with the global emphasis on energy efficiency and environmental sustainability, manufacturers are focusing on developing metal spinning machines that consume less energy and have a smaller carbon footprint. Initiatives such as improved machine design, energy-efficient motors, and waste reduction strategies are gaining traction.

Skilled labor shortage: As the metal spinning industry faces a skilled labor shortage, there is a growing trend towards user-friendly and intuitive machine interfaces. Manufacturers are investing in machines with simplified controls and automated features to reduce the reliance on highly skilled operators and facilitate easier training and operation.

Industry 4.0 and smart manufacturing: The integration of Industry 4.0 technologies, such as the Internet of Things (IoT), machine learning, and data analytics, is gaining momentum in the metal spinning machines market. Smart machines capable of self-monitoring, predictive maintenance, and data-driven optimization are becoming increasingly important for improved productivity and decision-making.

Key Drivers of Growth

Technological Advancements: The market's upward trajectory is significantly influenced by continuous technological advancements in metal spinning machines. Innovations in automation, precision control, and materials contribute to increased efficiency and expanded applications.

Growing Industrialization: With the global industrial sector on the rise, the demand for metal spinning machines has seen a proportional increase. These machines find application across diverse industries, including automotive, aerospace, and manufacturing, driving market growth.

Future Prospects and Opportunities

Emerging Markets: As industries continue to evolve, emerging markets present new opportunities for Metal Spinning Machine manufacturers. Increased industrialization in developing regions is expected to drive demand.

Focus on Sustainability: With a growing emphasis on sustainability, manufacturers are likely to invest in eco-friendly technologies and materials, aligning with global environmental trends.

Customization and Flexibility: Meeting the diverse needs of end-users through customizable solutions and flexible machine capabilities will be crucial for manufacturers looking to stay competitive.

CONTACT US:

276 5th Avenue, New York , NY 10001,United States

International: (+1) 646 781 7170

Email: help@intelmarketresearch.com

Follow Us On linkedin :- https://www.linkedin.com/company/24-market-reports