Weigh in Motion systems represent a significant advancement in transportation technology, offering real-time weighing capabilities without the need for vehicles to stop. This innovation plays a crucial role in various sectors, from transportation and logistics to infrastructure management, enhancing efficiency, safety, and regulatory compliance.

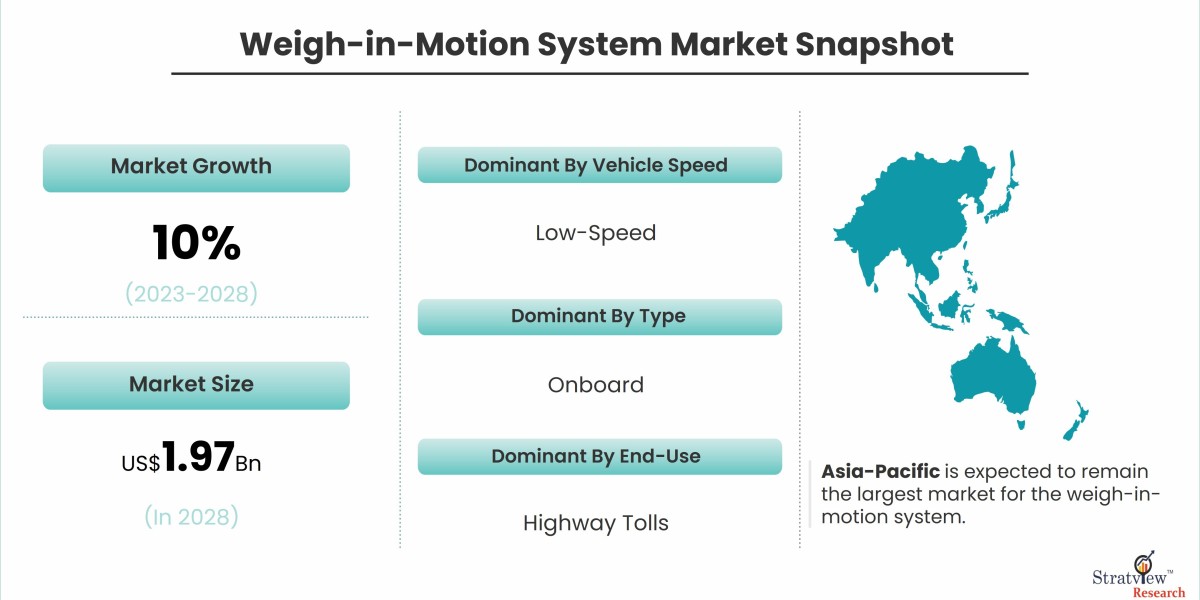

According to Stratview Research, the weigh-in-motion system market was estimated at USD 1.11 billion in 2022 and is likely to grow at a healthy CAGR of 10% during 2023-2028 to reach USD 1.97 billion in 2028.

Technology Behind Weigh in Motion Systems

Weigh in Motion systems utilize advanced sensor technologies embedded in the roadway or mounted on gantries above the road surface. These sensors detect and measure the weight of passing vehicles as they travel at normal speeds. The key components of a Weigh in Motion system typically include:

· Sensors: Piezoelectric sensors or bending plates installed in the roadway detect the dynamic forces exerted by vehicles and convert them into weight measurements.

· Data Acquisition Systems: Electronic devices capture and process sensor data in real-time, computing the weight of vehicles based on calibrated algorithms.

· Communication Infrastructure: Weigh in Motion Systems may integrate with existing communication networks or utilize wireless technology to transmit weight data to centralized monitoring centers or enforcement agencies.

Applications of Weigh in Motion Systems

Weigh in Motion systems find diverse applications across several industries:

· Transportation and Logistics: Weigh in Motion Systems play a critical role in monitoring axle weights and gross vehicle weights of trucks and commercial vehicles. This data aids in optimizing load distribution, preventing overloading, and ensuring compliance with weight regulations without disrupting traffic flow.

· Infrastructure Management: In infrastructure management, Weigh in Motion Systems provide essential data for assessing pavement wear and tear caused by heavy vehicles. This information supports maintenance planning and helps extend the lifespan of roads and bridges.

· Tolling and Enforcement: Weigh in Motion technology is integrated into toll collection systems to determine toll fees based on vehicle weight and classification. It also assists enforcement agencies in identifying overweight vehicles, enforcing weight limits, and issuing penalties for non-compliance.

· Smart Cities and Traffic Management: In smart city initiatives, Weigh in Motion systems contribute to traffic management by monitoring vehicle flows, optimizing signal timings, and improving overall transportation efficiency.

Benefits of Weigh in Motion Systems

The adoption of Weigh in Motion systems offers several benefits:

· Efficiency: Vehicles can be weighed seamlessly without the need for manual intervention, reducing delays and enhancing throughput at weigh stations.

· Safety: By identifying overweight vehicles in real-time, Weigh in Motion systems improve road safety by preventing accidents caused by overloaded trucks.

· Cost-Effectiveness: Weigh in Motion systems help optimize transportation logistics, reduce maintenance costs associated with overloaded vehicles, and streamline toll collection operations.

In conclusion, Weigh in Motion systems represent a pivotal technology in modern transportation and logistics, offering automated weighing solutions that enhance efficiency, safety, and regulatory compliance. As advancements in sensor technology and data analytics continue, the applications and benefits of Weigh in Motion systems are expected to expand, supporting sustainable and efficient transportation infrastructure worldwide.