Inline Viscosity Sensors are devices used to continuously measure the viscosity of liquids and semi-liquids directly within the flow of a process. These sensors provide real-time monitoring and control of viscosity, ensuring consistency and quality in various industrial applications such as food and beverage production, pharmaceuticals, chemicals, and petroleum.

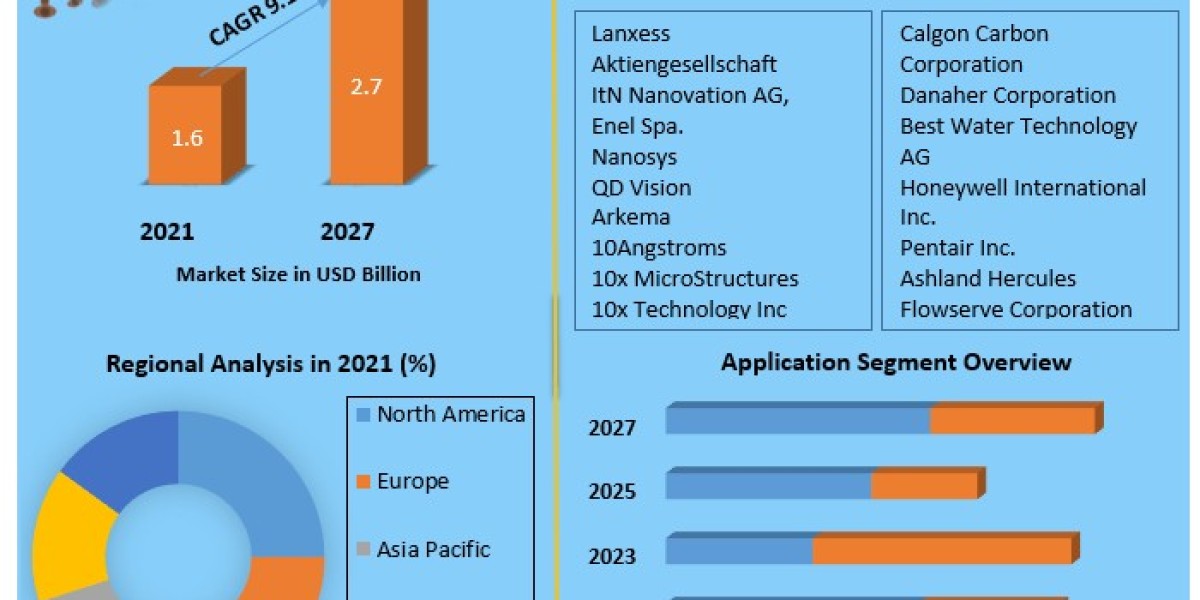

This research report provides a comprehensive analysis of the Inline Viscosity Sensors market, focusing on the current trends, market dynamics, and future prospects. The report explores the global Inline Viscosity Sensors market, including major regions such as North America, Europe, Asia-Pacific, and emerging markets. It also examines key factors driving the growth of Inline Viscosity Sensors, challenges faced by the industry, and potential opportunities for market players.

The global Inline Viscosity Sensors market has witnessed rapid growth in recent years, driven by increasing environmental concerns, government incentives, and advancements in technology. The Inline Viscosity Sensors market presents opportunities for various stakeholders, including Industrial, Commercial. Collaboration between the private sector and governments can accelerate the development of supportive policies, research and development efforts, and investment in Inline Viscosity Sensors market. Additionally, the growing consumer demand present avenues for market expansion.

Key Features:

The research report on the Inline Viscosity Sensors market includes several key features to provide comprehensive insights and facilitate decision-making for stakeholders.

Executive Summary: The report provides overview of the key findings, market trends, and major insights of the Inline Viscosity Sensors market.

Market Overview: The report provides a comprehensive overview of the Inline Viscosity Sensors market, including its definition, historical development, and current market size. It covers market segmentation by Type (e.g., Low Temperature, High Temperature), region, and application, highlighting the key drivers, challenges, and opportunities within each segment.

Market Dynamics: The report analyses the market dynamics driving the growth and development of the Inline Viscosity Sensors market. The report includes an assessment of government policies and regulations, technological advancements, consumer trends and preferences, infrastructure development, and industry collaborations. This analysis helps stakeholders understand the factors influencing the Inline Viscosity Sensors market’s trajectory.

Competitive Landscape: The report provides an in-depth analysis of the competitive landscape within the Inline Viscosity Sensors market. It includes profiles of major market players, their market share, strategies, product portfolios, and recent developments.

Market Segmentation and Forecast: The report segment the Inline Viscosity Sensors market based on various parameters, such as by Type, region, and by Application. It provides market size and growth forecasts for each segment, supported by quantitative data and analysis. This helps stakeholders identify growth opportunities and make informed investment decisions.

Technological Trends: The report should highlight the key technological trends shaping the Inline Viscosity Sensors market, such as advancements in Type One technology and emerging substitutes. It analyses the impact of these trends on market growth, adoption rates, and consumer preferences.

Market Challenges and Opportunities: The report identify and analyses the major challenges faced by the Inline Viscosity Sensors market, such as technical bottleneck, cost limitations, and high entry barrier. It also highlights the opportunities for market growth, such as government incentives, emerging markets, and collaborations between stakeholders.

Regulatory and Policy Analysis: The report should assess the regulatory and policy landscape for Inline Viscosity Sensors, including government incentives, emission standards, and infrastructure development plans. It should analyse the impact of these policies on market growth and provide insights into future regulatory developments.

Recommendations and Conclusion: The report conclude with actionable recommendations for stakeholders, such as Application One Consumer, policymakers, investors, and infrastructure providers. These recommendations should be based on the research findings and address key challenges and opportunities within the Inline Viscosity Sensors market.

Supporting Data and Appendices: The report include supporting data, charts, and graphs to substantiate the analysis and findings. It also includes appendices with additional detailed information, such as data sources, survey questionnaires, and detailed market forecasts.

Market Segmentation

Inline Viscosity Sensors market is split by Type and by Application. For the period 2019-2030, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value.

By Type

- Rotational Inline Viscosity Sensors

- Vibrational Inline Viscosity Sensors

- Ultrasonic Inline Viscosity Sensors

- Electromagnetic Inline Viscosity Sensors

- Capillary Inline Viscosity Sensors

- Others

By Technology

- Resonant Technology

- Vibrational Technology

- Electromagnetic Technology

- Ultrasonic Technology

- Others

- Low Temperature

- High Temperature

- Industrial

- Commercial

- North America (United States, Canada, Mexico)

- Europe (Germany, France, United Kingdom, Italy, Spain, Rest of Europe)

- Asia-Pacific (China, India, Japan, South Korea, Australia, Rest of APAC)

- The Middle East and Africa (Middle East, Africa)

- South and Central America (Brazil, Argentina, Rest of SCA)

- Brookfield

- Parker

- VAF Instruments

- Martechnic GmbH

- AVENISENSE

- Cambridge Viscosity

- Marimex Industries Corp.

- Hydramotion

- Emerson Electric

- Rheology Solutions

- Sofraser

Key Drivers:

- Increasing demand for real-time viscosity measurement: Inline viscosity sensors offer real-time measurement of viscosity, which is critical in many industrial processes, driving their adoption in various industries such as oil and gas, chemicals, and food and beverages.

- Growing demand for process automation: The increasing demand for process automation in various industries is driving the adoption of inline viscosity sensors, which can help optimize process efficiency and reduce costs.

- Technological advancements: Technological advancements in inline viscosity sensors, such as improved accuracy, reliability, and ease of use, are making them more attractive to end-users.

- Stringent regulations: Stringent regulations in various industries, such as the food and beverages industry, are driving the adoption of inline viscosity sensors to ensure product quality and safety.

- Increasing awareness of the benefits of inline viscosity sensors: Increasing awareness of the benefits of inline viscosity sensors, such as improved process control and reduced production costs, is driving their adoption in various industries.

Restrains:

- High cost: Inline viscosity sensors can be expensive, particularly for advanced models with high accuracy and sensitivity, which can limit their adoption in some industries and applications.

- Limited compatibility: Inline viscosity sensors may not be compatible with all types of liquids and process conditions, which can limit their adoption in some industries and applications.

- Maintenance requirements: Inline viscosity sensors require regular maintenance and calibration to ensure accurate and reliable measurement, which can increase their overall cost of ownership.

- Technical expertise: The installation and operation of inline viscosity sensors require technical expertise, which can limit their adoption in some industries and applications.

- Lack of standardization: The lack of standardization in inline viscosity sensor technology can make it difficult for end-users to compare and choose the right sensor for their specific application.