The aerospace printed circuit board market is essential for advancing electronic systems in aviation, defense, and space. Aerospace printed circuit board must be resilient, lightweight, and efficient to withstand extreme environmental conditions, including high altitudes, vibration, and temperature fluctuations. As the demand for sophisticated aerospace electronics grows, industry players must navigate a dynamic landscape filled with both promising opportunities and unique challenges.

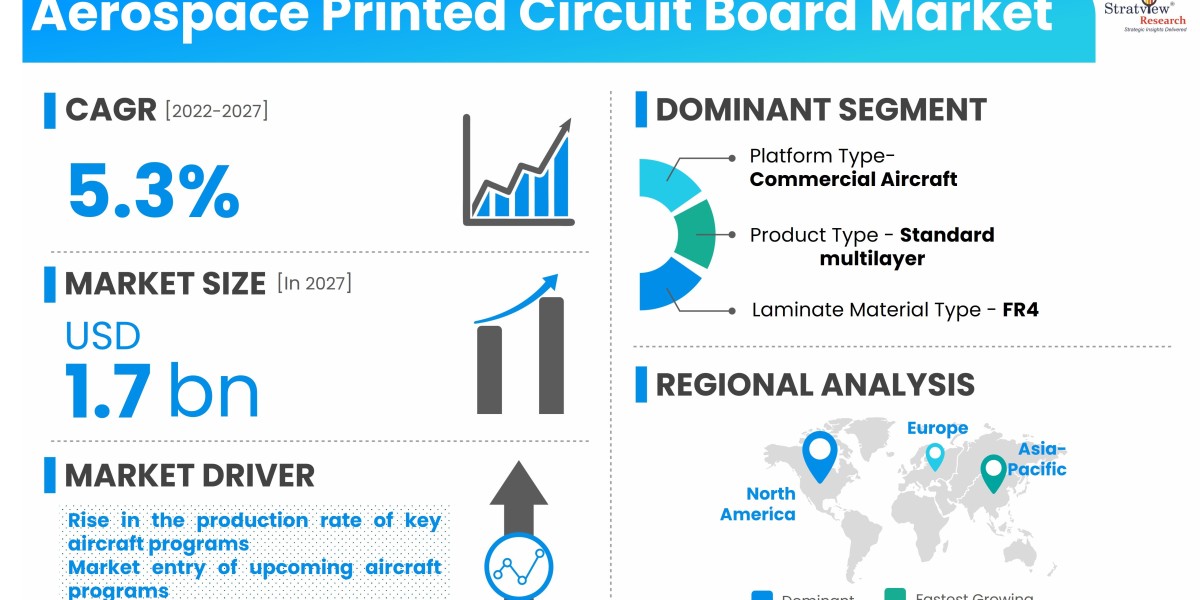

According to Stratview Research, the aerospace printed circuit board market is estimated to grow at a healthy CAGR of 5.3% during the forecast period to reach a value of USD 1.7 billion in 2027.

Opportunities in the Aerospace Printed Circuit Board Market

- Demand for Lightweight, High-Density Printed Circuit Boards Weight is a critical factor in aerospace, as lighter components improve fuel efficiency and reduce operational costs. This need has spurred innovation in high-density interconnect (HDI) printed circuit boards, which allow more circuitry in a compact, lightweight form. HDI printed circuit boards are particularly useful in space-constrained applications such as avionics and satellite systems, where maximizing functionality while minimizing weight is essential. Manufacturers focusing on these advancements are well-positioned to meet the industry’s growing needs.

- Expansion in UAV and Space Sectors The rapid growth in unmanned aerial vehicles (UAVs) and the global expansion of space exploration are creating a significant demand for robust, high-performance printed circuit boards. UAVs require compact, resilient printed circuit boards to support sophisticated functions like navigation, communication, and payload management. Likewise, the surge in satellite deployments and space missions necessitates radiation-resistant and durable printed circuit boards. Companies investing in specialized aerospace printed circuit boards can capitalize on the opportunities presented by these expanding sectors.

- Integration of IoT and Real-Time Data Capabilities The aerospace industry is increasingly adopting Internet of Things (IoT) technologies to enable real-time monitoring and predictive maintenance. IoT-enabled printed circuit boards support connected systems within aircraft, enabling remote diagnostics and enhancing operational safety. As IoT adoption in aerospace grows, manufacturers that develop printed circuit boards with seamless connectivity and data capabilities will capture a valuable market segment.

Challenges in the Aerospace PCB Market

- Stringent Regulatory Standards Aerospace printed circuit boards must comply with rigorous safety and performance standards to ensure reliability in critical systems. Certification processes are extensive, time-consuming, and costly, which can delay product development and increase expenses for manufacturers. Companies in this space must invest in rigorous testing and compliance protocols to meet the strict regulatory requirements of aviation and space applications.

- Material and Manufacturing Limitations Aerospace printed circuit boards require materials that can withstand harsh environmental conditions, such as high heat, shock, and radiation. High-performance materials like polyimide and ceramic substrates, while essential, are costly and challenging to manufacture. Moreover, miniaturizing components without compromising durability or functionality poses an added challenge, requiring advanced manufacturing techniques and expertise.

- Supply Chain Complexity and Cost Constraints The aerospace industry is highly sensitive to supply chain disruptions, especially given the reliance on high-quality components. Raw material shortages and fluctuations in component pricing can affect production timelines and profit margins, making it crucial for companies to maintain resilient and diversified supply chains.

Conclusion

Navigating the aerospace printed circuit board market requires balancing opportunities for growth with the complexities of regulatory standards, material demands, and supply chain challenges. Companies that can innovate within these parameters—by advancing lightweight, durable printed circuit boards with real-time data capabilities—will be well-positioned to succeed. As aerospace electronics continue to evolve, the potential for printed circuit board innovation is vast, paving the way for more advanced, reliable, and resilient systems across the aviation, defense, and space sectors.