The electric capacitor market has emerged as a vital component of modern technology, supporting industries ranging from renewable energy to automotive and consumer electronics. However, despite its significant growth potential, the market faces numerous challenges that could impact its trajectory. Here, we explore the key challenges and potential solutions that could shape the future of the electric capacitor market.

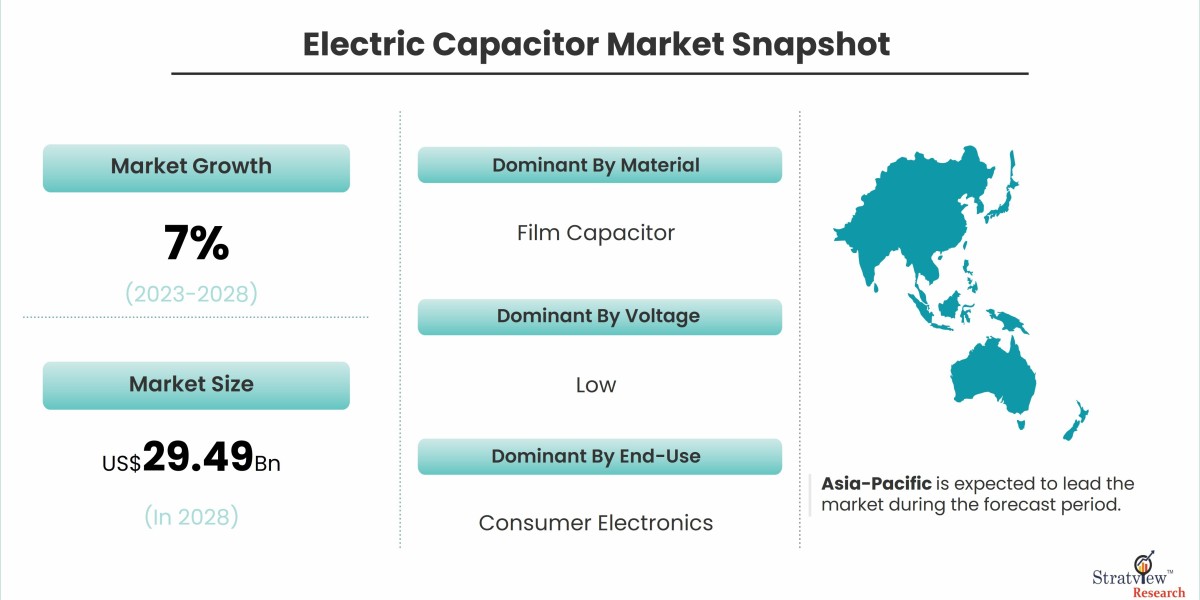

According to Stratview Research, the electric capacitor market was estimated at USD 19.6 billion in 2022 and is likely to grow at a CAGR of 7% during 2023-2028 to reach USD 29.49 billion in 2028.

Challenges in the Electric Capacitor Market

- Raw Material Price Volatility: Electric capacitors rely on materials like tantalum, aluminum, and ceramics, which are susceptible to price fluctuations due to supply chain disruptions, geopolitical tensions, and mining limitations. This volatility increases production costs and affects profit margins for manufacturers.

- Technological Limitations: While advancements have been made in capacitor technology, issues like limited energy density in traditional capacitors and the lack of scalability in advanced solutions such as supercapacitors remain significant hurdles. These constraints limit the adoption of capacitors in high-demand applications, such as electric vehicles and grid storage.

- Environmental Regulations: Strict environmental policies governing the use of hazardous substances in capacitors, such as lead and certain solvents, pose a compliance challenge for manufacturers. Adhering to these regulations often requires costly adjustments in manufacturing processes and product designs.

- Global Supply Chain Disruptions: The COVID-19 pandemic highlighted vulnerabilities in global supply chains, and the capacitor market was no exception. Delays in the availability of key components and logistical challenges disrupted production and delivery schedules, underscoring the need for more resilient supply chain models.

Solutions to Overcome Challenges

- Material Innovation: Investing in the development of alternative materials can mitigate the impact of raw material volatility. For instance, the exploration of graphene and other nanomaterials offers potential for creating capacitors with higher energy density and improved performance.

- Enhancing Manufacturing Efficiency: Adopting automation, advanced robotics, and AI-driven optimization in capacitor manufacturing can reduce production costs and improve scalability. These technologies enable precise process control and faster adaptation to market demands.

- Focus on Recycling and Sustainability: Establishing closed-loop recycling systems for capacitor components can address environmental concerns and reduce dependency on virgin raw materials. This approach aligns with global sustainability goals and enhances brand reputation.

- Strengthening Supply Chains: Diversifying supplier networks and adopting localized manufacturing strategies can improve resilience against global disruptions. Additionally, investing in digital tools for real-time supply chain monitoring can enhance decision-making.

Conclusion

While the electric capacitor market faces challenges like raw material dependency, regulatory hurdles, and supply chain vulnerabilities, solutions rooted in innovation, sustainability, and technological integration offer a path forward. By proactively addressing these issues, industry players can unlock the full potential of this essential market.