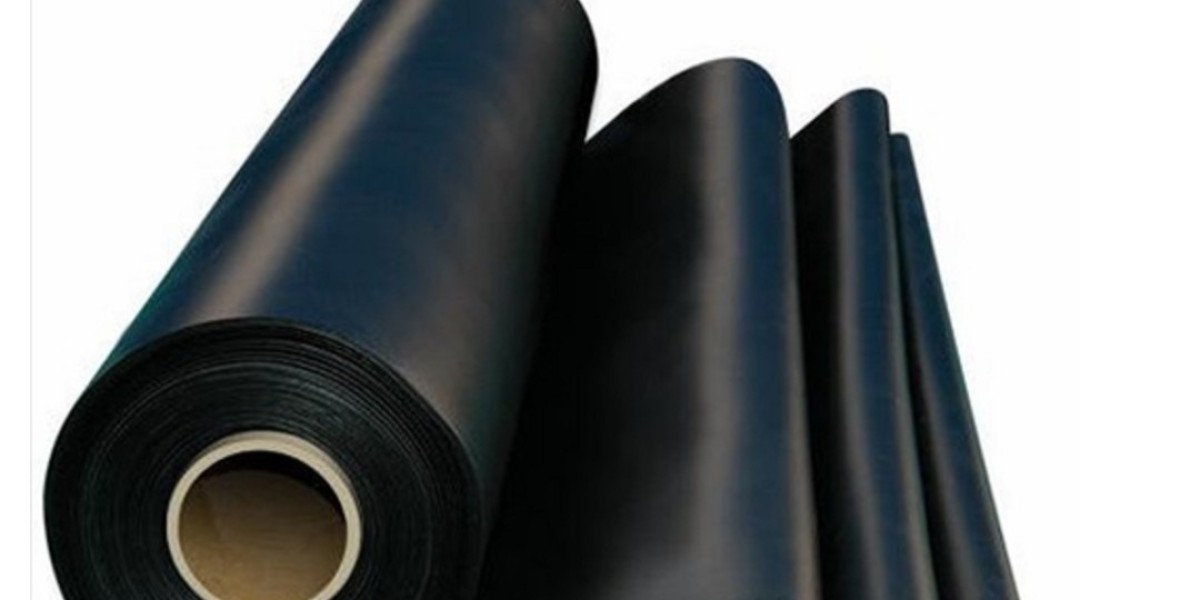

Introduction to Geomembrane Sheets

These sheets are designed to prevent the movement of fluids or gases through the soil layer, which is crucial in applications such as landfills, reservoirs, and aquaculture. In places like Delhi, a significant number of Geomembrane Suppliers in Delhi are emerging, catering to an increasing demand for quality materials. Understanding how these geomembrane sheets work and their wide range of applications can help in selecting the right product for specific needs.

Key Features of Geomembrane Sheets

Geomembranes are synthetic membranes composed of high-density polyethylene (HDPE), low-density polyethylene, or other materials. High-density polyethylene is particularly noted for its strength, chemical resistance, and longevity. One of the most critical features of HDPE Geomembrane Sheets is their thickness, which ranges from 0.5mm to 3mm, allowing for various applications based on the required durability and water resistance. These sheets can also be produced with additives to enhance UV resistance or flexibility. The versatility in design means they can be manufactured in various sizes and strengths tailored to specific project requirements.

Applications of Geomembrane Sheets

The applications of geomembrane sheets are vast and varied. They are primarily used for landfill liners, where they prevent leachate from contaminating the surrounding soil and groundwater. Another significant application is in water containment, such as reservoirs and ponds, where the geomembrane acts as a barrier to prevent water loss due to seepage. In agriculture, geomembranes are utilized for aquaculture, as they help to maintain the water quality necessary for fish farming. Additionally, they play a vital role in mining operations for tailings management and in the construction of green roofs, where they help manage water runoff while supporting plant life.

Environmental Impact and Sustainability

While geomembranes serve several essential functions in environmental protection, it’s crucial to consider their impact. The production and disposal of geomembrane sheets must be handled sustainably to minimize their environmental footprint. Many manufacturers are now focusing on recycling and developing biodegradable alternatives. Furthermore, the durability and longevity of materials like HDPE reduce the need for frequent replacements, thereby diminishing long-term environmental impacts. Sustainable practices and innovative approaches will be paramount in ensuring that the use of geomembranes aligns with global sustainability goals.

Installation Techniques for Geomembrane Sheets

Proper installation of geomembrane sheets is essential for ensuring their effectiveness. Techniques can vary based on the application, but common methods include excavator techniques, fusion welding, and mechanical fastening. The surface preparation is critical; the installation area should be free of any sharp objects or irregularities that might puncture the geomembrane. Additionally, proper training and expertise are required for installation to avoid issues that could compromise the membrane’s integrity. By following proper installation guidelines, project managers can maximize the performance and longevity of geomembrane sheets in their applications.

Economic Factors Related to Geomembrane Use

The economic aspect of utilizing geomembrane sheets plays a significant role in decision-making for various projects. While the initial costs can be considerable, especially for high-quality Hdpe Geomembrane Sheet, the long-term savings due to their durability and low maintenance needs often justify the investment. Furthermore, the reduction of environmental risks and compliance with regulatory standards can also provide financial benefits over time. Businesses considering the use of geomembrane sheets must evaluate not just the upfront costs but also the financial implications over the materials' lifespan.

Future Trends in Geomembrane Technology

The future of geomembrane sheets looks promising, driven by technological advancements and growing awareness of environmental issues. Innovations are paving the way for the development of smarter geomembranes that can provide real-time monitoring of potential leaks or failures. These advanced materials are integrated with sensors to detect moisture, temperature, and pressure changes, allowing for proactive maintenance. As industries seek more efficient and sustainable solutions, the demand for advanced geomembrane sheets will only continue to grow, leading to a more innovative landscape.

Conclusion: Importance of Choosing the Right Geomembrane

In conclusion, the advancements in geomembrane technology offer substantial benefits across numerous applications. The significance of sourcing materials from reputable Geomembrane Manufacturers in India cannot be overstated, as quality ensures the effectiveness and longevity of the geomembrane sheets. By understanding the applications, installation techniques, and economic factors associated with geomembranes, project managers can make informed decisions that align with their environmental and financial goals. Ultimately, the future of geomembranes lies in their versatility and adaptability to meet the specific needs of various industries.

Frequently Asked Questions

What materials are used in manufacturing geomembranes?

Geomembranes can be made from several materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), PVC, and polypropylene. Each material offers unique properties suitable for different applications.

How do I choose the right geomembrane thickness?

Choosing the right thickness depends on the specific application, environmental conditions, and expected loads. Factors such as soil type, temperature fluctuations, and potential puncture risks should also be considered.

Can geomembranes be repaired once installed?

Yes, geomembranes can be repaired using various methods, including patching techniques with compatible materials or fusion welding. Regular inspections can help identify issues early, making repairs more manageable.