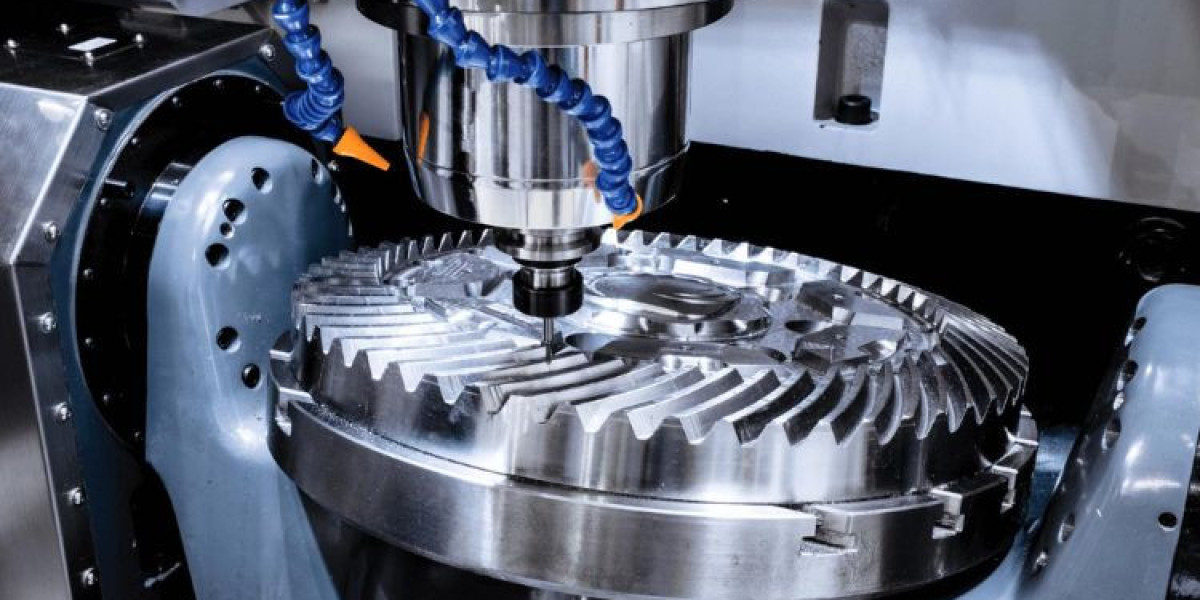

Milling machines are an essential component of modern manufacturing, providing precision and efficiency in the production of complex parts for a variety of industries. From automotive to aerospace and construction, these machines play a critical role in ensuring that parts are crafted with accuracy and consistency. The global milling machine market size attained a value of USD 84.26 billion in 2024. The milling machine market is further expected to grow in the forecast period of 2025-2033 at a CAGR of 7.2% to reach USD 157.02 billion by 2033. The Asia Pacific region is the fastest-growing market for the product, driven by rapid industrialization and increased demand from emerging economies. This blog post will explore the key drivers of growth in the milling machine market, as well as its segmentation, regional dynamics, and competitive landscape.

Global Milling Machine Market Overview

The global milling machine market is experiencing steady growth, driven by the increasing need for automation and precision in manufacturing processes. Milling machines, which are designed to shape and cut metal or other materials, are essential tools in the production of components used in various industries such as automotive, aerospace, defense, and construction.

As we move into the forecast period from 2025 to 2033, the demand for milling machines is expected to rise significantly due to advances in technology, such as the integration of automation and the increasing complexity of parts that need to be manufactured. The growing emphasis on precision and efficiency in production, as well as the global expansion of manufacturing activities, will continue to support the demand for milling machines across different sectors.

Market Segmentation

The milling machine market is highly diverse, with various machine types designed for different applications. Understanding the various market segments is crucial for identifying the growth opportunities and trends in the industry.

By Mechanism

Fraction Rice Milling Machines

Fraction rice milling machines are primarily used in the food processing industry for dehusking and milling rice. These machines offer precise control over the milling process, allowing rice to be processed into different fractions based on size, weight, and texture. As the demand for processed rice continues to grow, particularly in Asia-Pacific countries, the fraction rice milling segment is expected to witness steady growth.

Grind Rice Milling Machines

Grind rice milling machines are typically used for grinding rice into finer particles. These machines are vital for producing rice flour, which is an essential ingredient in various food products. As the global demand for rice-based food products grows, the market for grind rice milling machines will continue to expand, especially in regions where rice consumption is high.

By Direction

Vertical Type Mill Rollers

Vertical milling machines are designed with the spindle in a vertical orientation. This configuration is ideal for cutting and shaping materials that require a high degree of precision. Vertical type mill rollers are commonly used in applications such as drilling, boring, and reaming. Their ability to produce accurate parts in smaller spaces has made them popular in industries such as automotive and aerospace. The demand for vertical mills is expected to rise as industries increasingly prioritize compact, high-precision machining solutions.

Horizontal Mill Rollers

Horizontal milling machines, in contrast, have a horizontal spindle orientation and are more suitable for cutting large, heavy parts. These machines are often used in industries that require larger and more complex parts, such as the aerospace and defense sectors. Horizontal mill rollers offer higher efficiency and greater stability when working with heavy materials, making them indispensable for industrial-scale operations.

By End Use

Automotive

In the automotive industry, milling machines are crucial for producing parts with tight tolerances. Components such as engine blocks, transmission gears, and other mechanical parts require high precision, and milling machines are ideal for this purpose. The rise in automotive production, especially electric vehicles (EVs), is expected to drive the demand for advanced milling machines that can handle complex, high-performance components.

Aerospace and Defense

Aerospace and defense industries rely on milling machines to manufacture critical components such as turbine blades, fuselages, and landing gear, all of which require exceptional precision and durability. With growing investments in the aerospace sector and increasing defense budgets worldwide, the demand for milling machines in this segment is expected to rise significantly over the next decade.

Construction Equipment

The construction industry utilizes milling machines to create parts for heavy machinery and equipment used in construction projects. Milling machines play a crucial role in fabricating components for equipment such as bulldozers, cranes, and excavators. As global construction activities increase, especially in emerging economies, the demand for milling machines in this sector is projected to grow.

Others

Apart from automotive, aerospace, and construction, milling machines are also used in a variety of other industries, such as electronics, medical devices, and energy production. The versatility of milling machines allows them to cater to multiple sectors that require precision manufacturing.

Regional Analysis

North America

North America is home to several leading players in the milling machine market, and the region continues to dominate in sectors such as aerospace, automotive, and defense. The U.S. is particularly notable for its manufacturing output and technological innovations. As companies continue to invest in automation and precision manufacturing, the milling machine market in North America is expected to maintain steady growth during the forecast period.

Europe

Europe is another significant market for milling machines, driven by strong manufacturing industries in countries like Germany, Italy, and the United Kingdom. The aerospace sector, in particular, is a key consumer of high-precision milling machines. The ongoing demand for technological advancements in manufacturing processes will continue to propel the milling machine market in Europe.

Asia-Pacific

The Asia-Pacific region is the fastest-growing market for milling machines, fueled by rapid industrialization, increasing manufacturing output, and the growing demand for advanced machinery in countries such as China, India, and Japan. The automotive, aerospace, and construction industries in these countries are driving the growth of the milling machine market. Furthermore, the growing popularity of electric vehicles (EVs) in the region is also contributing to the rising demand for high-precision milling machines.

Latin America and the Middle East

In regions like Latin America and the Middle East, the milling machine market is poised for moderate growth. The construction and energy sectors are expanding, and as these industries develop, there will be an increased need for efficient milling machines. However, the growth in these regions will be slower compared to North America and Asia-Pacific.

Market Dynamics

Drivers

- Technological Advancements: Milling machines are evolving rapidly with the integration of automation, AI, and IoT, which is improving the precision and efficiency of operations. These advancements are making milling machines more attractive to industries looking to reduce labor costs and improve manufacturing quality.

- Increased Demand for Precision Parts: Industries such as automotive, aerospace, and defense require highly precise components, creating a strong demand for advanced milling machines.

- Industrial Growth in Emerging Markets: As economies in regions such as Asia-Pacific continue to industrialize, the demand for milling machines in manufacturing will increase.

Restraints

- High Initial Cost: Advanced milling machines come with a high upfront cost, which may deter smaller manufacturers from investing in the technology.

- Maintenance Requirements: Milling machines, especially those with advanced features, require regular maintenance and technical expertise, which can add to the overall operational costs.

Opportunities

- Smart Milling Machines: The development of smart, automated milling machines equipped with sensors and IoT capabilities offers opportunities for industries to streamline operations and reduce downtime.

- Emerging Markets: As manufacturing industries grow in regions such as Asia-Pacific, Latin America, and Africa, there is a significant opportunity for milling machine manufacturers to expand their reach.

Threats

- Competition from Alternative Machining Technologies: As alternative machining technologies, such as additive manufacturing, gain traction, milling machines face competition in sectors that require more flexibility and speed in production.

Competitive Landscape

The milling machine market is highly competitive, with several key players dominating the landscape. Companies such as DMG Mori, Haas Automation, Makino, and Mazak are at the forefront of technological innovation, offering advanced milling machines that meet the needs of various industries. These companies are investing in research and development to improve machine performance, precision, and automation capabilities.

The competitive dynamics of the market are further shaped by mergers, acquisitions, and partnerships. Leading manufacturers are consolidating their positions through strategic acquisitions to expand their product portfolios and market reach.

Milling Machine Market Forecast (2025-2033)

The global milling machine market is projected to grow at a CAGR of 7.2% from 2025 to 2033, reaching a value of USD 157.02 billion by 2033. Technological advancements, coupled with the growing demand for high-precision components across industries such as automotive, aerospace, and construction, will drive this growth. The Asia-Pacific region will continue to be the fastest-growing market, thanks to its expanding industrial base and the rising demand for advanced machinery.