Introduction to Atlas Copco Screw Compressor

Compressed air systems play a pivotal role in various industries, powering tools, machinery, and processes that are essential for daily operations. When it comes to reliability, efficiency, and performance, the Eutair Atlas Copco Screw Compressor stands as a beacon of excellence. In this blog post, we will delve into the world of compressors, focusing on the innovative Atlas Copco Screw Compressor, its applications, benefits, and how it compares to other alternatives.

Introduction to Atlas Copco Screw Compressor

The Atlas Copco Screw Compressor is a cutting-edge solution designed to deliver a consistent and reliable source of compressed air. Unlike traditional piston compressors, screw compressors use two rotating helical screws to compress air, resulting in smoother operation, higher efficiency, and increased longevity.

Applications and Industries

From manufacturing plants to automotive workshops, the applications of Atlas Copco Screw Compressors are diverse and impactful. They are commonly used to power pneumatic tools, spray painting equipment, CNC machinery, and much more. Industries that benefit from these compressors include manufacturing, construction, food and beverage, pharmaceuticals, and textiles, among others.

Advantages of Atlas Copco Screw Compressors

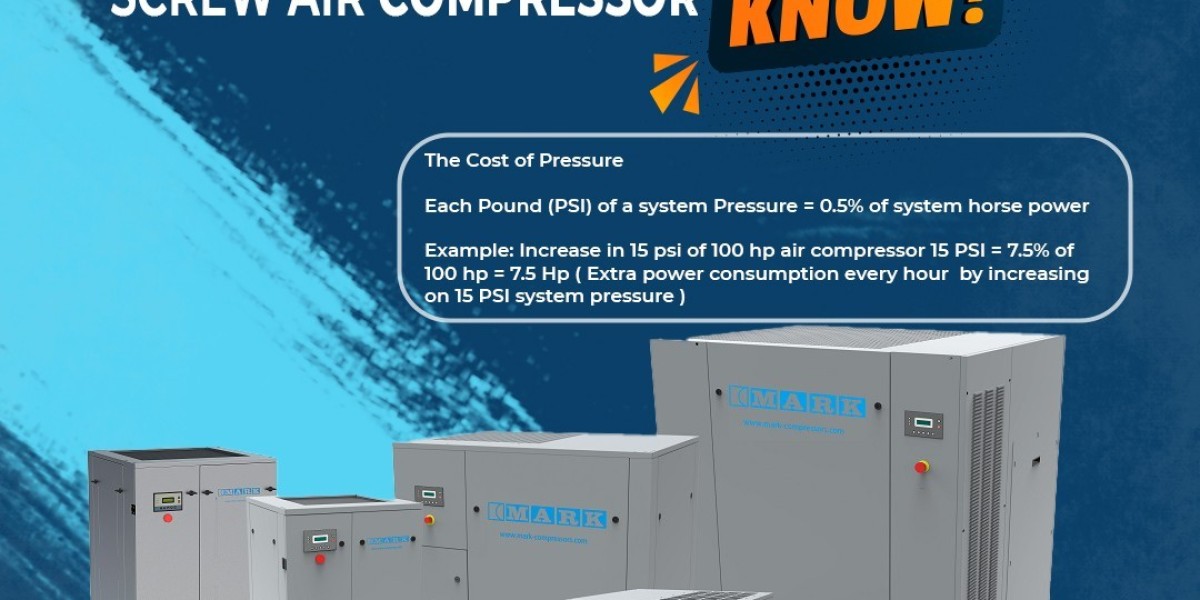

Energy Efficiency: One of the standout features of Atlas Copco Screw Compressors is their energy efficiency. The screw design minimizes energy wastage and provides consistent air output, leading to reduced operational costs.

Continuous Operation: Screw compressors can operate continuously, making them ideal for applications that require non-stop compressed air supply. This is in contrast to piston compressors that require more frequent stops and starts.

Low Noise Levels: These compressors are engineered with noise reduction in mind, ensuring a quieter working environment compared to some traditional compressor models.

Compact Design: Atlas Copco Screw Compressors are known for their compact footprint, saving valuable floor space in your facility.

Minimal Maintenance: With fewer moving parts and robust construction, these compressors demand less maintenance and have a longer service life.

Atlas Copco Air Compressor vs. Eutair: A Comparative Analysis

While Atlas Copco is a well-known name in the compressor industry, Eutair has been gaining attention recently. Let's compare these two brands:

Performance: Atlas Copco has a proven track record of delivering top-tier performance and efficiency. Eutair is emerging but might not have the same extensive history.

Innovation: Atlas Copco has a long history of innovation, constantly pushing the boundaries of compressor technology. Eutair might offer innovative features, but its innovations might not be as tested or established.

Service Network: Atlas Copco boasts a global service network, ensuring easy access to parts and maintenance. Eutair might have a more limited network depending on its market presence.

Customer Reviews: Atlas Copco likely has a substantial number of customer reviews and case studies attesting to its quality. Eutair might have fewer reviews available for reference.

Conclusion

When it comes to selecting a compressor that guarantees efficiency, reliability, and performance, the Atlas Copco Screw Compressor stands tall. Its innovative design, wide range of applications, and numerous advantages make it a solid investment for various industries. While newer players like Eutair might show promise, the established reputation and proven track record of Atlas Copco make it a compelling choice for businesses looking to optimize their compressed air systems.