Ball Float Steam Trap supplier in Morocco

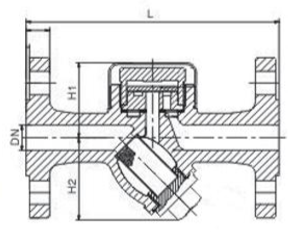

African Valve is the best Ball Float Steam Trap supplier in Morocco.A ball float steam trap is a type of steam trap used in industrial systems to remove condensate (liquid) from steam lines while preventing the loss of valuable steam. It operates based on the principle of buoyancy. The trap consists of a chamber with a ball float mechanism inside. As condensate accumulates in the chamber, the ball float rises, opening a valve to discharge the condensate. As the condensate level decreases, the ball float drops, closing the valve and preventing the escape of steam. This mechanism ensures efficient removal of condensate while retaining steam in the system, maximizing energy efficiency and preventing damage to downstream equipment.

Ball float steam traps are widely used in various applications, including steam heating systems, process industries, and power generation plants. They offer several advantages over other types of steam traps, such as mechanical simplicity, high durability, and reliable operation. The ball float mechanism is relatively unaffected by dirt or scale, reducing the risk of blockages and ensuring consistent performance. These traps also have a compact design and are easy to install and maintain.African Valve is a leading Ball Float Steam Trap supplier in Morocco Overall, ball float steam traps play a crucial role in steam systems by effectively managing condensate removal and preserving steam quality and energy efficiency.

Parts:

Body

Ball Float

Stem

Seat

Packing or Sealing System

Connections and Accessories

Advantages of a Ball Float Steam Trap:

Energy Efficiency: One of the primary advantages of a ball float steam trap is its ability to maximize energy efficiency. By effectively removing condensate from steam lines, it prevents the loss of valuable steam. This helps maintain optimal heat transfer and minimizes energy consumption, leading to significant cost savings over time.

Durability and Reliability: Ball float steam traps are known for their mechanical simplicity and robust construction. They are less prone to failure or malfunction compared to other types of steam traps. The ball float mechanism is relatively unaffected by dirt or scale, reducing the risk of blockages and ensuring consistent performance over an extended period.

Easy Installation and Maintenance: These steam traps have a compact design and are easy to install into steam systems. They require minimal maintenance, resulting in reduced downtime and operational costs. Routine maintenance typically involves inspecting and cleaning the trap to ensure optimal performance.

Applications of a Ball Float Steam Trap:

Steam Heating Systems: Ball float steam traps are commonly used in steam heating systems, such as those found in commercial buildings, hospitals, and universities. They efficiently remove condensate from the heating system, ensuring proper functioning and preventing damage to equipment, such as heat exchangers or radiators.

Power Generation Plants: Power plants utilize steam for electricity generation. Ball float steam traps play a critical role in condensate removal from steam turbines, boilers, and other equipment. Efficient condensate removal ensures optimal turbine performance and prevents water hammer, which can lead to equipment damage.

Petrochemical and Refining: Petrochemical and refining facilities use steam in various processes, such as distillation, cracking, and reforming.

Description:

Body: Carbon Steel, Stainless Steel, Ductile Iron

Float ball: SS304

Bolt: SS304

Bracket: SS304

Pin: SS304

Bonnet: Carbon Steel, CF8

Disc: 2Cr13, SS304

Seat: 2Cr13, SS304

Gasket: Graphite+SS304

Nominal Diameter: DN15 to DN100

Nominal Pressure: PN10 to PN64

Visit our website to know more:

https://www.africanvalve.com/p....roduct-category/ball

Pilot operated safety valve Supplier in Tunisia

African valve is a premium Pilot Operated Safety valve supplier in Tunisia. A pilot-operated safety valve is a type of pressure relief valve that is commonly used in industrial applications to protect equipment and systems from overpressure. Unlike direct spring-loaded safety valves, which rely on a spring to open and close the valve, pilot-operated safety valves utilize a combination of a main valve and a pilot valve.

The main valve is responsible for controlling the flow of fluid or gas, while the pilot valve is connected to a separate sensing line that monitors the pressure in the system. When the pressure exceeds the set point, the pilot valve sends a signal to the main valve, causing it to open and release the excess pressure. This design allows for more precise and reliable pressure relief, as the pilot valve can be adjusted to specific pressure requirements and can respond quickly to changes in pressure. African valve is a leading Pilot operated safety valve supplier in Tunisia. Pilot-operated safety valves are often used in high-pressure and high-capacity applications, providing efficient protection against overpressure conditions and preventing potential damage to equipment and systems.

Parts :

Main Valve

Pilot Valve

Sensing Line

Set Point Adjustment

Overpressure Lift Mechanism

Types:

Direct-acting Pilot-Operated Safety Valve

Balanced Bellows Pilot-Operated Safety Valve

Piston-Type Pilot-Operated Safety Valve

Remote Pilot-Operated Safety Valve

High-Capacity Pilot-Operated Safety Valve

Advantages:

Accurate Pressure Control: Pilot-operated safety valves provide precise pressure control due to the separate pilot valve and sensing line. This allows for better accuracy in maintaining the desired pressure set point.

High Capacity: These safety valves can handle high flow rates and large volumes of fluid or gas, making them suitable for applications with high capacities.

Quick Response: Pilot-operated safety valves are designed to respond quickly to changes in pressure, ensuring prompt relief when the pressure exceeds the set point. This helps to prevent equipment damage and maintain system integrity.

Adjustable Set Point: The set point of pilot-operated safety valves can be easily adjusted to match specific pressure requirements, providing flexibility and customization.

Remote Monitoring and Control: In remote pilot-operated safety valves, the pilot valve can be located at a different location from the main valve, allowing for remote monitoring and control of pressure relief.

Applications:

Process Industries: Pilot-operated safety valves are commonly used in various process industries, including oil and gas, chemical, pharmaceutical, and refining. They provide reliable pressure relief in pipelines, storage tanks, reactors, and other equipment.

Power Generation: Pilot-operated safety valves are crucial in power generation applications, such as steam boilers, turbines, and pressure vessels. They ensure safe operation by preventing overpressure situations.

Compressed Air Systems: Pilot-operated safety valves are utilized in compressed air systems to safeguard against overpressure, ensuring the proper operation and longevity of pneumatic equipment.

Aerospace Industry: Pilot-operated safety valves are found in aircraft hydraulic systems and fuel lines, providing pressure relief and protection against potential hazards.

Description:

Material: Ductile Iron, WCB, WCC, WC9, WC6,SS304, SS316,CF8M, SS316L, SS904L, Cast iron

Size: 1/2″ to 24″

Ends: Socket weld butt weld, flanged, threaded

class:150-300 PN6to PN25

Operation: handwheel ,electric actuated ,pneumatic actuated

Visit our website to know more:

https://www.africanvalve.com/p....roduct-category/safe

Thermodynamic Steam Trap Supplier in South Africa

African Valve is a leading Thermodynamic Steam Trap Supplier in South Africa .A thermodynamic steam trap is a type of steam trap used in steam systems to efficiently remove condensate from the system while preventing the loss of live steam. It operates based on the principle of thermodynamics, utilizing the difference in pressure between steam and condensate to facilitate the trap's operation.The thermodynamic steam trap consists of a disc or valve that opens and closes based on the dynamic changes in pressure. When steam flows into the trap, it passes through the disc, causing it to lift and allow the steam to pass through. As condensate forms, the pressure decreases, causing the disc to close. This closure prevents the loss of steam while allowing only the condensate to be discharged. Once the pressure equalizes, the disc opens again to allow the cycle to repeat.

Thermodynamic steam traps are known for their simplicity, durability, and ability to handle high-pressure and high-temperature applications. They are commonly used in various industrial processes, including steam heating systems, steam lines, process equipment, and other applications where efficient removal of condensate and prevention of steam loss are essential. The thermodynamic steam trap's reliable operation and low maintenance requirements make it a popular choice in steam systems.African Valve is a premium Thermodynamic Steam Trap Supplier in South Africa .

Parts:

Body

Gate or Blade

Stem

Seat

Packing or Sealing System

Connections and Accessories

Advantages :

Simple and Robust Design: Thermodynamic steam traps have a relatively simple construction, consisting of few moving parts. This design makes them more resistant to wear and tear, leading to longer service life and reduced maintenance requirements.

High Reliability: Thermodynamic steam traps are known for their high reliability, ensuring consistent operation even in challenging conditions. They can handle high-pressure differentials and fluctuations, making them suitable for a wide range of steam system applications.

Efficient Condensate Removal: These traps efficiently discharge condensate from steam systems. The thermodynamic principle relies on the velocity and pressure difference of steam and condensate to open and close the trap, ensuring prompt removal of condensate without significant steam loss.

Rapid Response: Thermodynamic steam traps have quick response times, allowing them to open and close rapidly in response to changes in steam flow or condensate load. This responsiveness ensures efficient condensate removal and minimizes the risk of steam blockages.

Wide Operating Range: Thermodynamic steam traps can operate across a wide range of pressures and temperatures, making them versatile for various steam system applications. They are commonly used in both low-pressure and high-pressure steam systems.

Applications :

Process Industries: Thermodynamic steam traps find extensive use in process industries such as chemical, petrochemical, pharmaceutical, and food processing plants. They are ideal for applications where rapid condensate removal is required to prevent equipment damage, maintain process efficiency, and ensure product quality.

Power Generation: Thermodynamic steam traps play a vital role in power plants, ensuring the efficient operation of steam turbines and condensers. They help remove condensate from steam lines and condenser tubes, preventing the accumulation of water and maintaining optimal steam quality.

Commercial Buildings: Thermodynamic steam traps are also used in commercial buildings with steam heating systems. They help maintain efficient heat transfer in radiators and prevent condensate buildup, ensuring comfortable indoor temperatures and energy savings.

Description:

Material: Ductile iron, Cast Iron, Carbon Steel, cast steel (WCB, WCC, LCC, LCB, WC6, WC9), Stainless Steel (SS316, SS304, CF8).

Class: 150 – 1500, PN10 – PN250.

Size: ½” to 2”.

Ends: Socket weld, butt weld, flanged, threaded.

Visit our website to know more:

https://www.africanvalve.com/p....roduct-category/ther